Manufacturing Scheme Finder

Find Your Best Government Scheme Match

Select which challenges your business faces to see which government schemes could help. Based on the article, we'll show you relevant options and potential benefits.

Which manufacturing challenges do you face?

Your Recommended Government Schemes

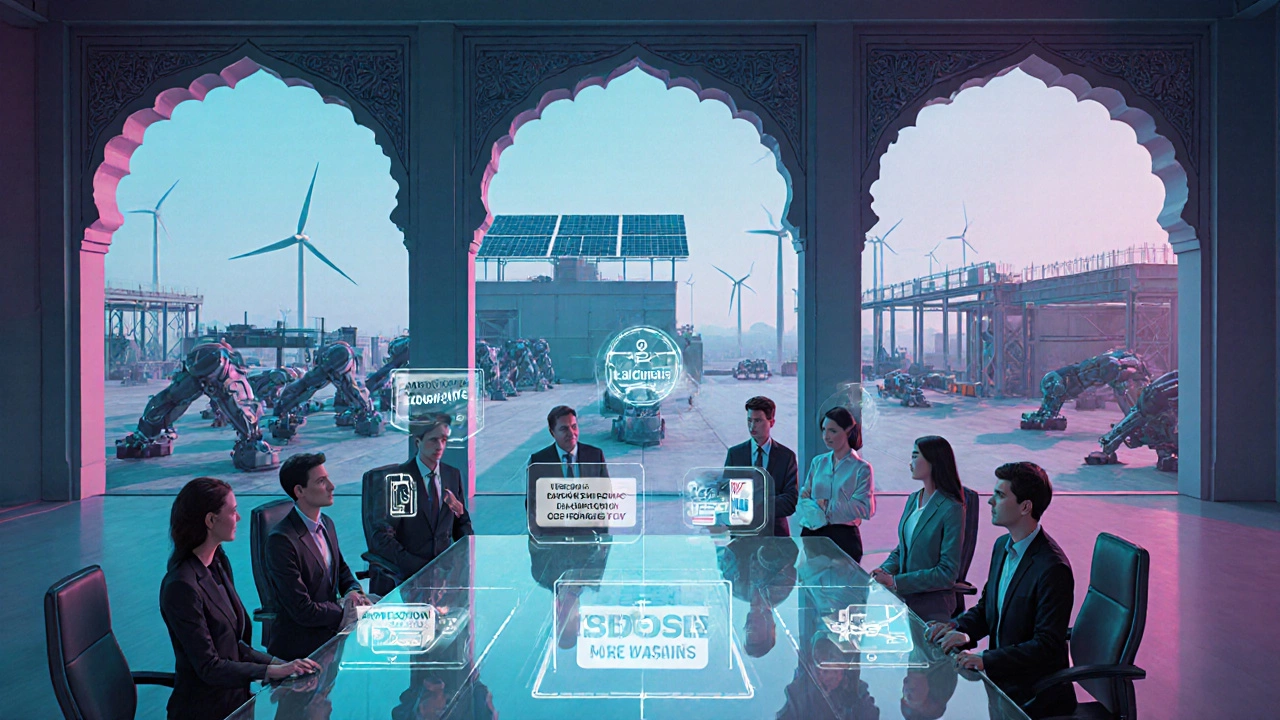

When you hear Manufacturing is a key engine of economic growth that turns raw materials into finished goods, you imagine factories humming, jobs flowing, and exports rising. Yet many businesses today complain that the sector feels more like a maze than a machine. Why? The answer isn’t one single factor - it’s a mix of structural hurdles, market pressures, and policy gaps that turn ordinary production into a daily headache.

Top Three Structural Hurdles Holding Manufacturing Back

Every manufacturer, from a small‑scale metal shop in Auckland to a multinational automotive plant in Europe, faces a similar set of roadblocks. Below are the three most common ones, illustrated with real‑world snapshots.

- Supply Chain Disruptions: Global logistics have become a wild card. A single port strike in the U.S. can delay component deliveries for a New Zealand furniture maker, inflating lead times by weeks.

- Labor Shortage & Skill Gap: Younger workers often shy away from factory floors, while older technicians retire faster than they can be replaced. The result is a 12% vacancy rate in the UK metal‑working sector, according to a 2024 industry survey.

- Energy Costs & Sustainability Pressures: Rising electricity prices in Australia and stricter carbon reporting in the EU force plants to either absorb higher bills or invest in costly retrofits.

These challenges aren’t isolated; they interact. A supply‑chain delay can increase overtime, which amplifies labor fatigue, which then drives up energy use as older equipment runs longer. To untangle the knot, governments have rolled out a suite of Government Schemes policy tools designed to offset specific industry costs or stimulate investment. Let’s see how they line up against the problems.

How Government Schemes Aim to Solve Each Problem

Below is a quick‑look table that matches the three head‑liners with the most common types of public support.

| Problem | Typical Scheme | Key Benefit | Example Country |

|---|---|---|---|

| Supply Chain Disruptions | Logistics Grant & Port Infrastructure Funding | Reduced transit time, subsidised freight | Germany |

| Labor Shortage & Skill Gap | Apprenticeship Subsidy & Skills Training Voucher | Lower hiring cost, faster up‑skill | Australia |

| Energy Costs & Sustainability | Renewable Energy Incentive & Carbon Tax Offset | Lower electricity bills, greener credentials | Canada |

Deep‑Dive into the Three Problem Areas

1. Supply Chain - The Global Domino Effect

Think of a modern car. It needs steel from China, chips from Taiwan, rubber from Thailand, and paint from the U.K. When any link snaps, the whole line stalls. The pandemic showed how fragile that chain can be, but the shock has turned into a chronic risk. Companies now face longer lead times, higher buffer inventories, and more freight‑cost volatility.

Supply Chain the network of suppliers, transport routes, and logistics hubs that deliver inputs to a factory is especially vulnerable to geopolitical tension and climate‑driven disruptions. A 2023 study by the World Bank found that 38% of manufacturers rate supply‑chain reliability as their top concern.

What works? Governments in the EU have begun funding “smart port” upgrades that use AI to optimise cargo handling, cutting average turnaround by 15%. In New Zealand, the Ministry of Business, Innovation & Employment runs the “Regional Logistics Hub” programme, offering low‑interest loans to set up local distribution centres. These moves shave days off delivery, easing the pressure on factory floor schedules.

2. Labor Shortage & Skills Gap - The Human Element

Automation can’t replace every hand. Skilled machinists, welders, and process engineers still command the line. Yet the average age of a manufacturing worker in the U.S. is 46, and retirements are outpacing new hires. A recent survey by the International Labour Organization reported a 9% decline in manufacturing employment in the EU between 2020‑2024, largely due to staffing gaps.

Labor Shortage a condition where firms cannot find enough qualified workers to fill open positions hurts productivity and spikes overtime costs. Meanwhile, the Skill Gap the disparity between the abilities workers possess and the competencies employers need forces factories to rely on older equipment that’s harder to maintain.

Government solutions range from apprenticeship subsidies to immigration pathways for skilled technicians. Australia’s “Skilled Occupation List” grants fast‑track visas for CNC operators, while the U.K. introduced a £1,200 per‑apprentice voucher scheme in 2024, covering up to 50% of training costs. For small‑scale producers, the New Zealand “Manufacturing Skills Boost” offers a 30% wage offset for the first six months of a new hire.

3. Energy Costs & Sustainability - Money Meets the Planet

Factories are energy‑hungry. In 2024, the average electricity price for industrial users in the EU rose to €0.20kWh, a 12% jump from the previous year. For a medium‑size food‑processing plant, that’s an extra €250,000 annually.

Energy Costs expenses incurred from electricity, gas, or other power sources needed to run production equipment directly erode margins. At the same time, consumers and regulators are demanding greener processes. Carbon‑tax regimes in Canada and Sweden penalise high‑emission plants, nudging firms toward renewable solutions.

Enter the Renewable Energy Incentive government financial support for installing solar, wind or bio‑energy systems. In 2025, New Zealand launched a $150million grant that covers up to 60% of solar‑panel installation for manufacturers under 200employees. The incentive not only cuts electricity bills but also earns carbon‑credit sales that can be sold on the market.

Why Policy Alone Can’t Fix the Puzzle

Even the best‑designed scheme hits limits if it doesn’t align with on‑ground realities. For instance, a logistics grant may fund a new rail link, but without skilled operators, the line won’t run at capacity. Likewise, an apprenticeship voucher is useless if schools lack the equipment to teach modern CNC programming.

That’s why a Holistic Approach coordinated strategy that blends financial aid, training, infrastructure, and regulatory reform works best. In the Netherlands, the “Manufacturing 2030” roadmap merges tax credits, green‑energy subsidies, and a national apprenticeship network, delivering a 4% productivity lift across the sector in three years.

Practical Checklist for Manufacturers Facing These Problems

- Map your supply‑chain hotspots and identify which logistics grants you qualify for.

- Run a skills audit: list roles where turnover exceeds 15% and explore apprenticeship vouchers.

- Calculate your current energy spend per unit; compare it against available renewable‑energy incentives.

- Engage with local chambers of commerce - they often have templates for grant applications.

- Set up a cross‑functional task force to align finance, HR, and operations around each scheme’s requirements.

Following this list can turn a vague idea of “getting help” into concrete actions that shave costs and boost output.

Future Outlook - What’s Next for Manufacturing Policy?

Governments are already eyeing emerging tech as a lever for growth. The UK’s 2026 “Advanced Manufacturing Tax Relief” will give extra credits for AI‑driven quality‑control systems. Canada plans a “Hydrogen‑Ready” grant to help heavy‑industry plants transition to low‑carbon fuel sources.

At the same time, trade policy will keep reshaping cost structures. The Pacific‑Australia Free Trade Agreement, set to start in 2027, promises lower tariffs on raw aluminium - a boon for New Zealand’s aerospace component makers.

Staying ahead means watching policy calendars as closely as market data. Subscribe to industry newsletters, attend the annual “Manufacturing Policy Forum,” and keep your grant‑application timeline flexible.

Takeaway

Manufacturing isn’t a problem by accident; it’s a symptom of intersecting supply‑chain fragility, workforce shortages, and energy pressures. manufacturing challenges can be mitigated when governments pair financial incentives with real‑world training and infrastructure upgrades. The key is to match each hurdle with the right scheme, monitor outcomes, and adapt quickly.

Frequently Asked Questions

What are the most common government schemes for manufacturers?

Typical schemes include logistics grants, apprenticeship subsidies, renewable‑energy incentives, carbon‑tax offsets, and R&D tax credits. Each tackles a specific pain point such as supply‑chain delays or skill shortages.

How can a small factory qualify for a logistics grant?

First, identify the nearest qualifying transport hub. Then prepare a cost‑benefit analysis showing reduced lead times and job creation. Most programs require proof of matching funds, but the contribution is often as low as 10% of the project budget.

Are apprenticeship vouchers only for large firms?

No. Many countries cap the voucher amount per apprentice, making it affordable for SMEs. For example, the UK’s 2024 scheme caps at £1,200 per apprentice, which a small metal‑fabrication shop can easily cover for a couple of trainees.

What’s the best way to reduce energy costs without huge capital spend?

Start with an energy audit to pinpoint inefficient equipment. Then apply for renewable‑energy incentives that fund solar panels or waste‑heat recovery. Many programs also offer low‑interest loans for retrofits, letting you pay back over time from the saved bills.

Will upcoming trade agreements affect manufacturing incentives?

Yes. Reducing tariffs on raw materials can lower production costs, making certain incentive programs more attractive. The Pacific‑Australia Free Trade Agreement, for instance, will cut aluminium duties, benefitting NZ aerospace parts makers.