Chemical Manufacturing Profit Calculator

Profitability Estimator

Calculate potential profits for high-margin chemicals based on your production parameters.

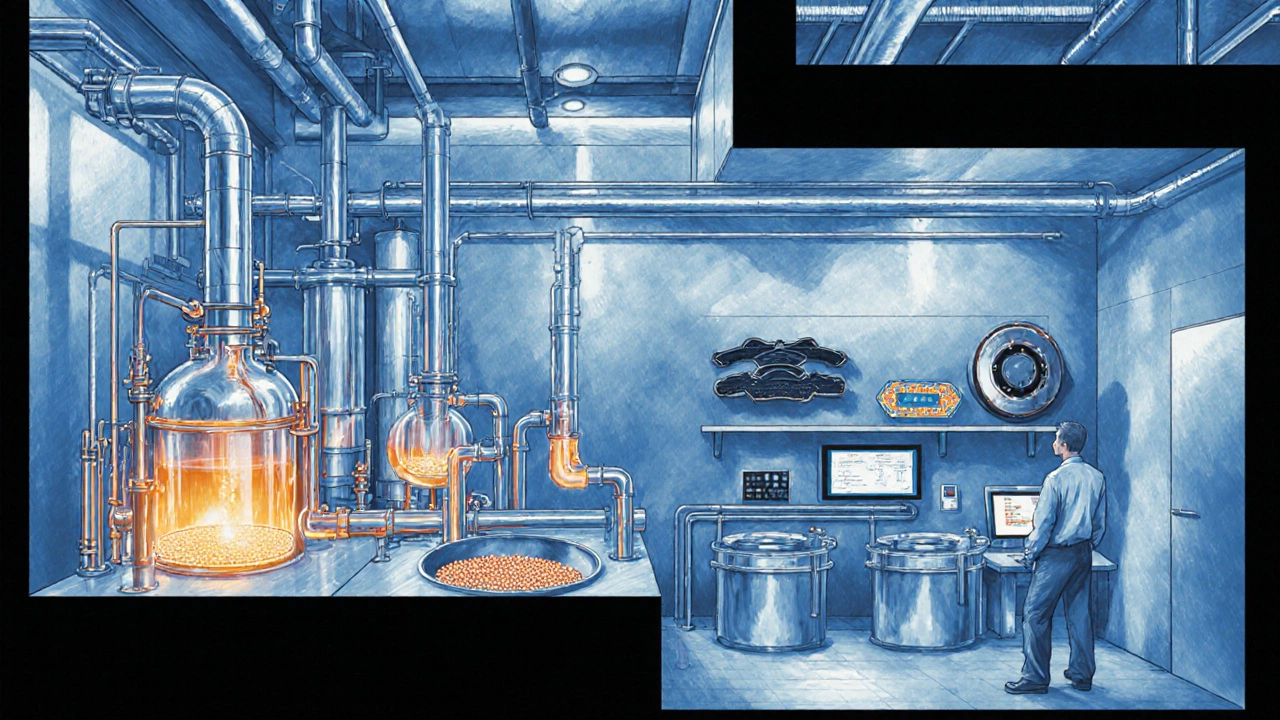

When eyeing the Indian market, Specialty chemicals is a segment of chemicals that command higher prices because they serve niche applications like pharmaceuticals, electronics, and high‑performance polymers. The question on many entrepreneurs’ minds is simple: which chemical is most profitable for a new or expanding plant? This guide walks through the top earners, how they make money, and what you need to watch out for before you invest.

Why Profitability Varies Across Chemicals

Profit margins in the chemical industry aren’t set by a single factor. They emerge from a mix of raw‑material cost, energy consumption, capital intensity, regulatory burden, and market demand. A product that looks cheap to produce can still deliver thin margins if the market is saturated, while a high‑cost material can be lucrative if it serves a critical, low‑competition niche.

In India, three forces push certain chemicals into the high‑margin zone:

- Import dependence: If most of the world supply comes from abroad, domestic producers can price a premium.

- Value‑added applications: Chemicals that become part of finished goods-like polymers in electronics-tend to earn more.

- Regulatory incentives: Government schemes for green chemicals or pharma‑grade intermediates often include tax breaks or subsidised electricity.

Top Five High‑Profit Chemicals in India (2025)

| Chemical | Typical Gross Margin | Key End‑Use Sectors | Domestic Production Share | Average Selling Price (USD/ton) |

|---|---|---|---|---|

| Phenol | 25‑30% | Resins, pharmaceuticals, adhesives | 35% | 1,800 |

| Isopropyl alcohol | 22‑28% | Disinfectants, cosmetics, cleaning agents | 45% | 1,200 |

| Ethylene glycol | 20‑25% | Automotive antifreeze, polyester fibers | 40% | 1,400 |

| Urea | 18‑22% | Fertilizers, animal feed, NOx control | 60% | 600 |

| Polyethylene (HDPE) | 15‑20% | Packaging, pipes, toys | 55% | 1,100 |

The numbers above come from industry reports and recent Ministry of Chemicals and Fertilisers data (2024‑2025). Notice that the highest margins cluster around specialty intermediates like phenol and isopropyl alcohol, while bulk polymers and fertilizers sit a notch lower.

Deep Dive: Phenol - The Profit Engine

Phenol, often called “oil of wood,” is the poster child for high profitability. India imports about 65% of its phenol demand, leaving a sizable gap for local producers. The gross margin of 25‑30% stems from three factors:

- Feedstock advantage: Phenol is derived from cumene, which is made from benzene and propylene. Indian petro‑refineries now run cumene units at lower-than‑global average costs.

- High‑value downstream products: Phenol feeds into phenolic resins used for brake pads, circuit boards, and fire‑retardant plastics. These downstream markets price for performance, not volume.

- Export potential: Neighboring Bangladesh and Sri Lanka still import most of their phenol. Exporting at a modest premium can add 5‑8% to the margin.

To get started, a medium‑size plant (≈50kt/yr) needs an investment of roughly USD150million, with a payback period of 4‑5years under current price levels.

Other Contenders Worth Watching

Below are quick snapshots of the other top earners, each with a unique profit driver.

- Isopropyl alcohol is a solvent and disinfectant that saw a demand spike after the COVID‑19 pandemic. The domestic market now consumes 1.2million tonnes annually, with a 22‑28% margin thanks to easy scalability and relatively low raw‑material costs (propane).

- Ethylene glycol serves the booming automotive sector as antifreeze and as a building block for PET polyester. Its margin (20‑25%) benefits from stable ethylene feedstock pricing in Indian refineries.

- Urea is the world’s most produced nitrogen fertilizer. Although margins look modest, volume drives total profit. Government subsidies on natural gas (the main feedstock) boost the margin to 18‑22%.

- Polyethylene (HDPE) is a versatile polymer used in packaging and construction. The sector benefits from a strong domestic packaging demand and a well‑established supply chain, delivering 15‑20% margins.

Cost Drivers You Can’t Ignore

Even the most profitable chemicals can turn sour if you overlook hidden costs. Here are the three biggest expense traps:

- Energy bills: Chemical plants are energy‑hungry. In 2025, the average industrial electricity tariff in India is ₹7 per kWh. Securing captive power or renewable PPAs can shave 3‑5% off the margin.

- Environmental compliance: The Ministry of Environment tightened effluent standards for phenol and formaldehyde in 2024. Investing in treatment plants early avoids fines and production stoppages.

- Raw‑material volatility: Crude‑derived feedstocks (benzene, propylene, natural gas) can swing 15‑20% year‑on‑year. Hedging contracts or vertical integration (owning a small cracker) stabilises costs.

Government Schemes That Boost Profitability

The Indian government actively encourages high‑value chemical manufacturing. A few schemes you should map into your financial model:

- PLI (Production‑Linked Incentive) for Specialty Chemicals: Offers up to 10% subsidy on capital expenditure for projects that produce >10kt/yr of phenol, isopropyl alcohol, or ethylene glycol.

- VAT exemption on raw‑material imports for pharma‑grade intermediates: Cuts import duty from 10% to 0% for approved chemicals.

- Solar Power Procurement for Industrial Zones: Enables plants in designated clusters to buy solar electricity at ₹3 per kWh, which can improve the overall margin by 2‑3%.

Key Takeaways

- Phenol, isopropyl alcohol, ethylene glycol, urea, and HDPE lead the Indian profit charts.

- Specialty chemicals earn higher margins because of import gaps, value‑added downstream use, and government incentives.

- Energy, compliance, and feedstock volatility are the top cost challenges - plan for them early.

- Leverage PLI and renewable‑energy schemes to shave a few percentage points off cost.

- Start with a medium‑scale plant (50‑100kt/yr) to balance CAPEX and market risk.

Getting Started: A Practical Checklist

- Choose your target chemical based on market gap and your capital capacity.

- Run a detailed cash‑flow model - include raw‑material price forecasts for the next 5years.

- Secure land in an industrial cluster that offers power‑and‑water guarantees.

- Apply for relevant PLI or subsidy programmes before finalising the plant layout.

- Plan for a dedicated effluent‑treatment unit to meet the latest EPA‑India standards.

- Negotiate long‑term off‑take contracts with downstream users (e.g., resin manufacturers, pharma firms).

- Set up a hedging strategy for benzene, propylene, or natural‑gas inputs.

Frequently Asked Questions

Frequently Asked Questions

Which chemical offers the quickest payback period?

Isopropyl alcohol typically provides the fastest payback (3‑4years) because its plant design is modular, raw‑material costs are low, and demand is steady across disinfectant and cosmetics markets.

Do I need a special licence to produce phenol?

Yes. Phenol is listed under the Hazardous Chemicals (Production, Storage, and Sale) Act. You’ll need a consent from the State Pollution Control Board and a licence from the Ministry of Chemicals and Fertilisers.

Can I export chemicals directly from an Indian plant?

Export is allowed, but you must register with the Directorate General of Foreign Trade (DGFT) and comply with REACH or other destination‑country regulations. Many Indian producers ship phenol and isopropyl alcohol to SAARC nations under preferential duty rates.

How does the PLI scheme impact my ROI?

The PLI offers a cash incentive of up to 10% of eligible capital spend, which can cut the effective CAPEX by ₹15‑20crore for a 50kt plant. That translates to a 1‑2year reduction in the payback horizon.

What are the biggest regulatory risks?

Changing effluent limits for phenol and formaldehyde, and tightening emissions norms for VOCs in solvent production, are the top risks. Staying ahead with a robust environmental management system keeps you compliant and avoids costly shutdowns.