Manufacturing Method Selector

Select your primary manufacturing requirement to identify the most suitable method:

Machining

Subtractive process - removes material

Additive

Builds parts layer by layer

Forming

Reshapes material without adding/removing

Recommended Manufacturing Method

Select your requirements and click "Analyze Best Manufacturing Method" to get recommendations.

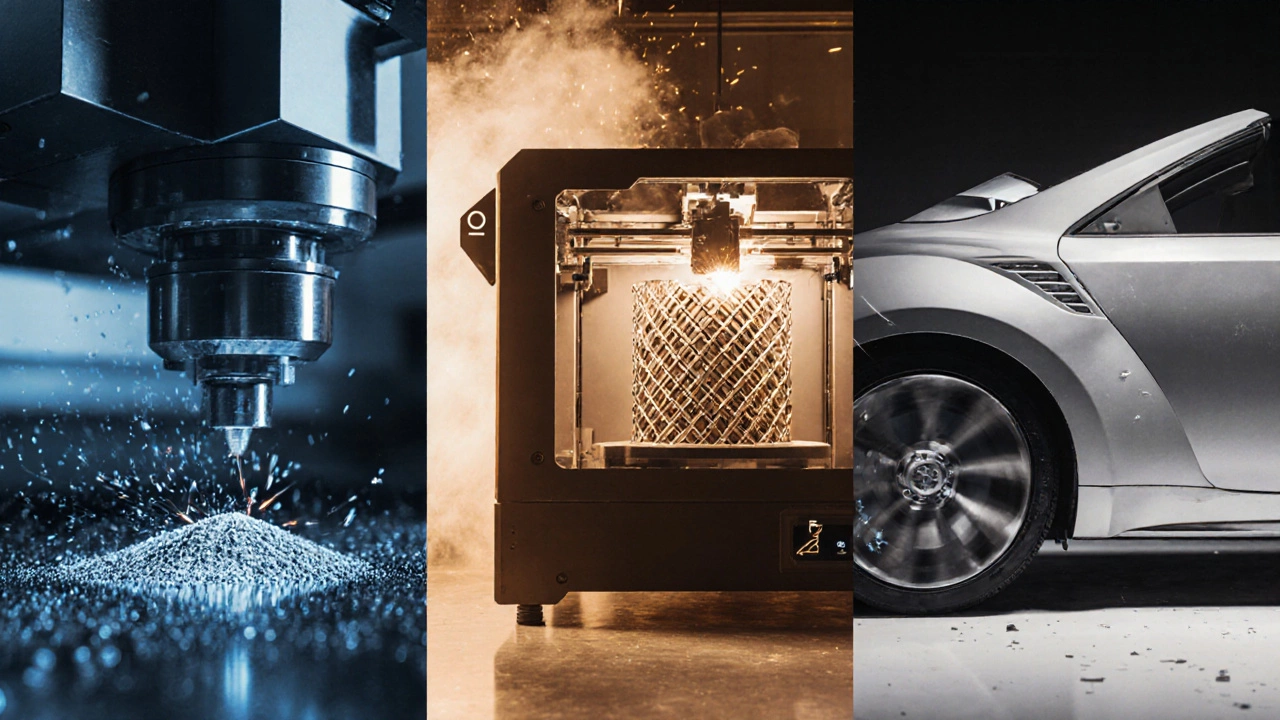

Manufacturing methods are the fundamental ways companies turn raw material into finished products. They shape everything from smartphone casings to steel bridges. Knowing the three major approaches-machining, additive manufacturing, and forming-helps you pick the right process, control costs, and avoid costly design mistakes.

Quick Overview

If you need a fast answer: machining removes material (subtractive), additive manufacturing builds up material layer by layer, and forming reshapes material without removing or adding mass. Each method has its sweet spot, typical industries, and trade‑offs.

1. Machining - The Subtractive Workhorse

Machining is a subtractive process where a cutting tool removes unwanted material from a solid workpiece until the desired shape emerges. Modern shops rely on CNC (computer‑numerical‑control) machines that follow precise G‑code instructions.

- Typical materials: metals (aluminum, steel, titanium), plastics, composites.

- Key industries: aerospace, automotive, medical device manufacturing.

- Advantages: high dimensional accuracy (<0.01mm), excellent surface finish, wide material compatibility.

- Disadvantages: material waste (up to 30% removed), higher energy consumption for hard metals, longer lead times for complex geometries.

Because the tool physically contacts the workpiece, tool wear is a major cost driver. Selecting the right cutter material-carbide, ceramic, or coated steel-can extend tool life by 40%.

2. Additive Manufacturing - Building Layer by Layer

Additive manufacturing, often called 3D printing, creates objects by depositing material in successive layers based on a digital model. Popular technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

- Typical materials: thermoplastic polymers (PLA, ABS), photopolymers, metal powders (stainless steel, Inconel), ceramic slurries.

- Key industries: rapid prototyping, aerospace (lightweight brackets), dental and medical implants, custom tooling.

- Advantages: near‑zero waste, ability to produce complex internal channels, fast iteration cycles for design validation.

- Disadvantages: slower build rates for large parts, anisotropic mechanical properties, higher per‑part cost for mass production.

One practical tip: orient the part so that critical features face the build platform. This reduces support material and improves surface quality on functional faces.

3. Forming - Reshaping Without Adding or Removing

Forming encompasses a family of processes that plastically deform a workpiece into a new shape while keeping its volume constant. Common techniques include stamping, rolling, forging, and deep drawing.

- Typical materials: sheet metal (steel, aluminum, copper), bars and rods for forging.

- Key industries: automotive body panels, appliance housings, structural steel components.

- Advantages: high production rates, low material waste, excellent part strength due to work‑hardening.

- Disadvantages: high upfront tooling cost (dies, molds), limited design flexibility, need for precise material temperature control.

When designing for forming, keep bend radii above the material’s minimum radius to avoid cracking. Using finite‑element simulation early can shave weeks off tool development.

How the Three Methods Compare

| Attribute | Machining (Subtractive) | Additive Manufacturing | Forming (Deformation) |

|---|---|---|---|

| Material removal vs. addition | Removes material | Adds material layer‑by‑layer | Reshapes existing material |

| Typical lead time | 1-3 weeks for low‑volume runs | Days for prototypes, weeks for large builds | Hours to days once tooling is ready |

| Cost per part (high volume) | Medium‑high (tool wear) | High (material and machine time) | Low - amortized over large batch |

| Design flexibility | Limited by tool access | Very high - complex internal features | Low - geometry constrained by dies |

| Common defects | Tool chatter, burrs | Layer adhesion issues, surface roughness | Springback, cracking |

Choosing the Right Method for Your Project

Think of the decision like picking the right tool for a DIY job. Ask yourself three questions:

- Quantity? If you need a few prototypes, additive manufacturing wins. For 10,000+ identical brackets, forming is cheapest.

- Geometry complexity? Intricate internal channels (like heat exchangers) are only feasible with 3D printing.

- Material performance? High‑strength aerospace shafts often require CNC‑machined titanium, while a car door panel is perfect for stamping.

In many real‑world projects you’ll combine methods-e.g., 3D‑print a complex hub, then CNC‑machine the mounting faces, finally assemble into a forged frame.

Common Pitfalls and How to Avoid Them

- Ignoring tolerances early. Each method has a typical tolerance range. Design a part with machining tolerances (<±0.02mm) in mind, or you’ll end up re‑machining costly prototypes.

- Underestimating tooling cost. For forming, a new die can cost $20,000-$100,000. Run a quick breakeven analysis before committing.

- Overlooking material anisotropy. Additive parts are weaker along the build direction. Align load‑bearing features with the strongest axis.

- Skipping material qualification. Not all polymers survive the high temperatures of metal‑based SLS. Verify compatibility sheets from material suppliers.

Checklist: Evaluating Manufacturing Methods

- Define target production volume.

- Sketch geometry and note any undercuts or internal channels.

- Select candidate materials and check their process‑specific property charts.

- Estimate tool or machine time and calculate per‑part cost.

- Run a short pilot-either a CNC‑machined sample, a 3D‑printed prototype, or a stamped pilot run.

- Validate dimensional accuracy, surface finish, and mechanical performance against design specifications.

Future Trends Shaping the Three Methods

Automation and AI are blurring the lines between these traditional categories. Smart CNC machines now self‑optimize cutting paths, reducing waste by 15%. Hybrid machines combine additive and subtractive heads, letting you print support structures then mill them away in one set‑up. In forming, high‑strength aluminum alloys are being hot‑formed at lower temperatures thanks to advanced lubricants, expanding the range of parts that can be stamped.

Frequently Asked Questions

Which method is best for producing a one‑off metal prototype?

For a single metal part, additive manufacturing (metal‑laser sintering) typically offers the fastest turnaround and the least material waste. CNC machining is an alternative if the geometry is simple and tolerances are tight.

Can I combine machining and forming in the same production line?

Yes. A common workflow is to stamp a blank part, then perform a final CNC‑machining step for critical dimensions such as bolt‑hole locations or surface finish on mating surfaces.

What are typical surface roughness values for each method?

Machining can achieve Ra0.2µm or better with fine tools. Additive processes usually start around Ra5-10µm, requiring post‑processing for smoother finishes. Formed sheet metal often lands at Ra1.6µm after a standard deburring step.

How does material waste differ among the three methods?

Forming typically generates less than 2% waste because the material is reshaped, not cut. Machining can waste 20‑30% depending on part geometry. Additive manufacturing can be almost waste‑free for powders, though support structures add 5‑15% extra material.

Is it cheaper to outsource or buy in‑house equipment?

For low‑volume or highly specialized parts, outsourcing to a specialist shop avoids the capital expense of CNC or 3D‑printing machines. If you anticipate steady demand above 5,000 units annually, investing in a dedicated line-especially for forming-often yields lower per‑part cost.