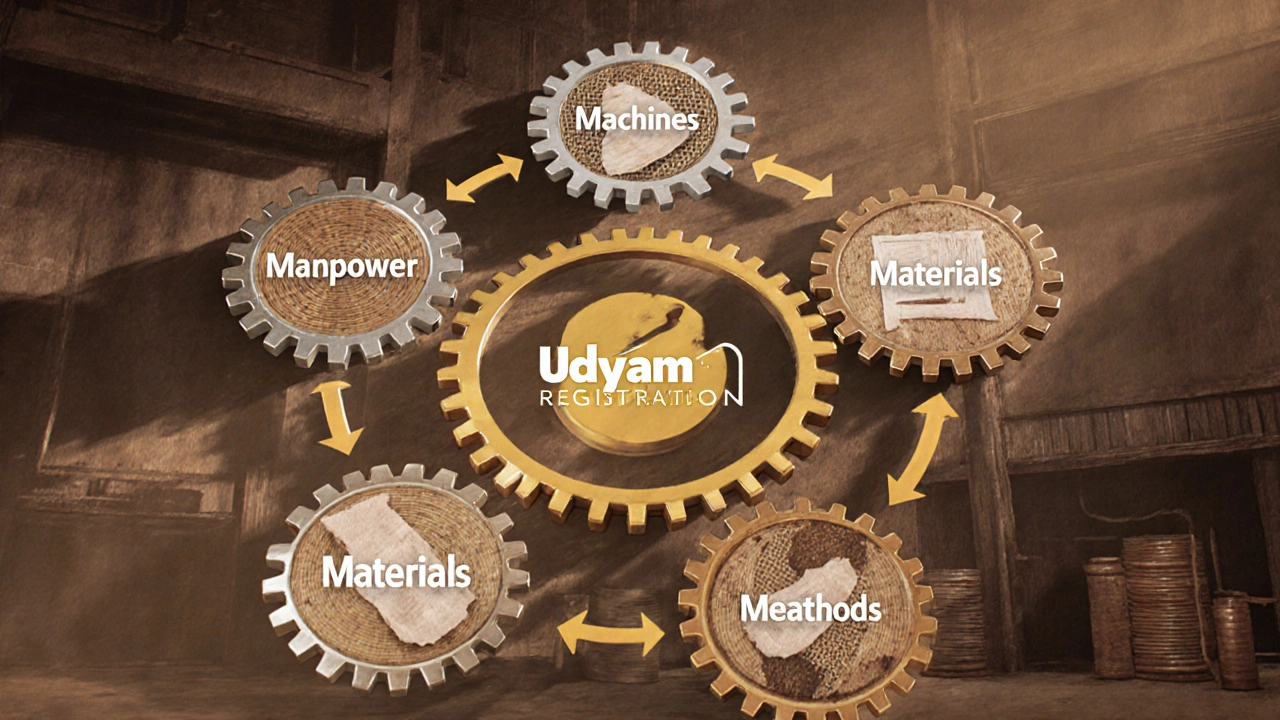

If you run a small factory or are thinking about starting one, you’ve probably heard the term 5 M's of manufacturing. It’s not some fancy consultant jargon-it’s a simple, proven framework used by factories across India, Southeast Asia, and Africa to cut waste, boost output, and qualify for government grants. Many small manufacturers miss out on subsidies and training programs because they don’t understand these five basics. But once you get them right, your production lines run smoother, your costs drop, and your chances of getting government support go up dramatically.

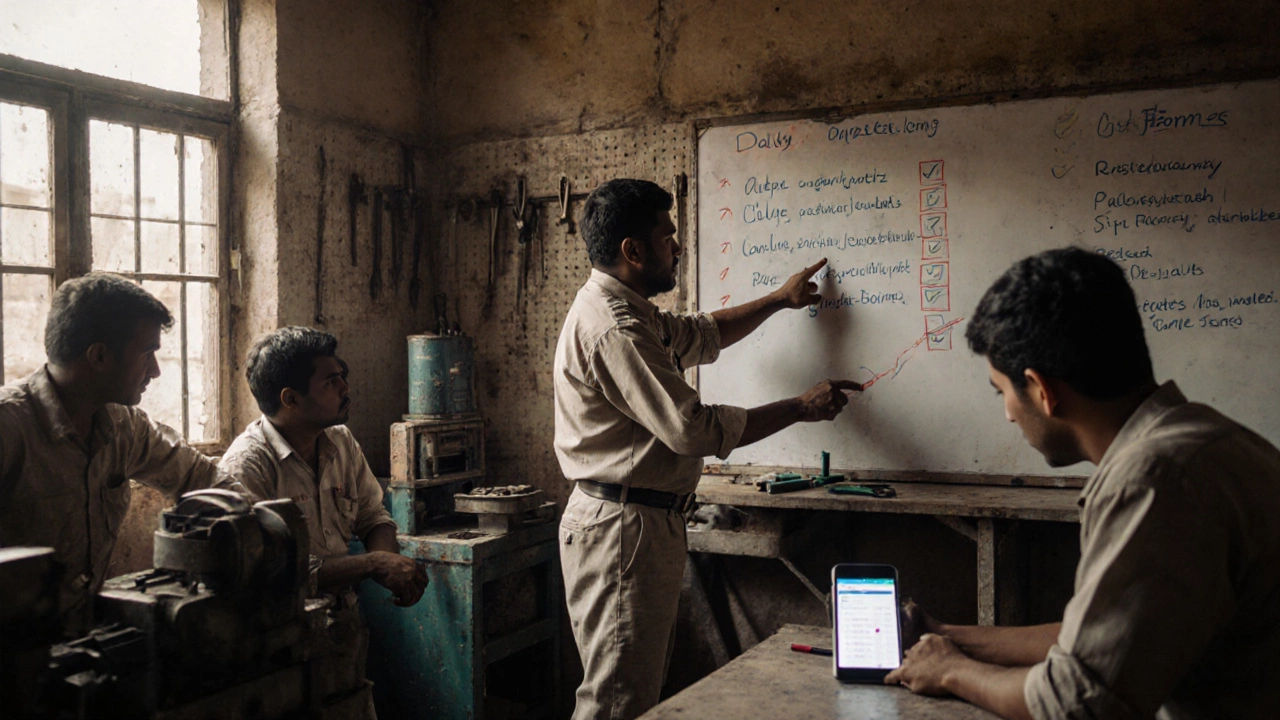

Manpower: The Human Engine

Manpower isn’t just about hiring workers. It’s about having the right people in the right roles, trained properly, and motivated to keep things running. In small factories, one person often handles three jobs. That’s fine-if they know what they’re doing. But when operators aren’t trained on machine safety or quality checks, defects pile up, downtime increases, and inspections fail.

Under India’s Pradhan Mantri Kaushal Vikas Yojana (PMKVY), factories that train workers in standardized manufacturing skills get up to 100% reimbursement for training costs. But to qualify, you need records: who was trained, what they learned, and proof they passed. Many small owners skip this because they think it’s paperwork. It’s not. It’s your ticket to free training and cash incentives.

Start simple: Make a list of every job on your floor. Assign one person per task. Track attendance. Use free apps like Google Forms to log training sessions. You don’t need an HR department-just consistency.

Machines: Tools That Don’t Break Down

Machine breakdowns cost small manufacturers 20-30% of their monthly output, according to a 2024 survey by the National Manufacturing Competitiveness Council. It’s not always the machine’s fault-it’s maintenance.

The 5 M's don’t say ‘buy the newest machine.’ They say: ‘keep your machines running.’ That means daily cleaning, weekly lubrication, monthly calibration. In textile mills in Surat and electronics assembly units in Noida, factories that follow a basic 10-minute daily checklist cut machine failures by 60% in six months.

Government schemes like Make in India and Technology Upgradation Fund Scheme (TUFS) offer up to 25% subsidies for machine upgrades-but only if you can show you’ve been maintaining your existing equipment. No maintenance logs? No subsidy. Keep a simple notebook. Write down every repair, every oil change, every part replaced. That’s your proof.

Materials: Quality Starts at the Door

Bad materials don’t just make bad products-they make bad reputations. In plastic manufacturing in Jaipur, one batch of low-grade resin caused 300 defective bottles. The customer canceled the next 12 orders. That’s not a material issue-it’s a sourcing issue.

The 5 M's require you to control your materials from the moment they arrive. That means:

- Checking supplier certificates (even for small orders)

- Storing raw materials properly (humidity, temperature, dust)

- Labeling everything clearly-no more ‘mystery bins’

- Testing samples before full production

Under the Udyam Registration scheme, factories that document their material quality checks get priority in government procurement bids. If you’re supplying to hospitals, schools, or local governments, this matters. You don’t need a lab. A simple digital scale, moisture meter, or visual checklist is enough. Document it. File it. Use it.

Methods: The Right Way to Do Things

Every factory has a ‘way things are done.’ But is it the best way? In furniture workshops in Moradabad, one team spent 45 minutes assembling a chair. Another, using the same tools, did it in 22 minutes. The difference? A standardized method.

Methods mean documenting your process step by step. Not in a 50-page manual-just a simple flowchart or photo guide. Show workers: where to stand, which tool to pick up, how to check the fit. In electronics assembly units in Bengaluru, factories that created visual work instructions reduced assembly errors by 70%.

Government training programs under Skill India provide free templates for process mapping. Download one. Fill it out for your top three products. Train your team on it. Record a 2-minute video of the process on your phone. That’s your standard. Repeat it. Every day.

Measurement: If You Can’t Measure It, You Can’t Improve It

You can’t fix what you don’t measure. Yet, most small factories don’t track anything beyond ‘how many did we make today?’

The 5 M's demand four basic metrics:

- Output per shift (units made)

- Defect rate (% of bad products)

- Machine uptime (% of time running)

- Material waste (kg or % used vs. expected)

Use paper and pen if you have to. Stick a whiteboard on the wall. Update it every shift. In steel rolling units in Rourkela, factories that started tracking these four numbers saw productivity jump 18% in four months-not because they bought new machines, but because they started seeing where things went wrong.

Government schemes like Manufacturing Extension Partnership (MEP) offer free consultants to help small factories set up these metrics. You don’t need software. You need consistency. Measure. Record. Review. Adjust.

Putting It All Together: How This Helps You Get Government Support

The 5 M's aren’t just for running a better factory-they’re the checklist government officials use to approve subsidies, loans, and training programs. When a district officer visits your plant, they’re not looking for fancy equipment. They’re looking for:

- Workers who know their jobs (Manpower)

- Machines that are maintained (Machines)

- Materials that are checked (Materials)

- Processes that are written down (Methods)

- Numbers that are tracked (Measurement)

If you can answer yes to all five, you’re eligible for:

- Up to ₹5 lakh in equipment subsidies under TUFS

- Free skill training for 10+ workers under PMKVY

- Priority in public procurement tenders

- Lower interest rates on MSME loans

Don’t wait for an inspector to show up. Do the work now. Start with one area-say, measurement. Track your output and defects for two weeks. Then fix one thing. Then move to manpower. Then materials. You don’t need to fix everything at once. Just start.

Common Mistakes to Avoid

Most small manufacturers fail at the 5 M's-not because they’re lazy, but because they misunderstand them:

- Thinking ‘Manpower’ means hiring more people → It means training the people you have.

- Buying a new machine instead of fixing the old one → Maintenance beats upgrades every time.

- Assuming materials are fine because ‘they’ve always worked’ → Suppliers change. Quality slips. Check every batch.

- Skipping documentation because ‘we know what we’re doing’ → Government schemes need proof. Your memory isn’t enough.

- Measuring only output → Without defect rate and waste, you’re flying blind.

If you’re spending money on training, machines, or materials, but not seeing results-go back to the 5 M's. One of them is broken. Find it. Fix it.

Where to Start Today

You don’t need a consultant. You don’t need a big budget. Here’s your 7-day plan:

- Day 1: List every job on your floor. Assign names.

- Day 2: Pick one machine. Write down its daily maintenance steps.

- Day 3: Pick one material. Check its supplier certificate. Take a photo.

- Day 4: Film a 90-second video of your most common production process.

- Day 5: Start tracking output and defects on a whiteboard.

- Day 6: Visit the Udyam Portal. Register your factory if you haven’t.

- Day 7: Call your local MSME office. Ask: ‘What schemes can I qualify for with these 5 M's?’

That’s it. No apps. No software. Just action. The 5 M's aren’t theory. They’re your roadmap to a better factory-and better government support.

Are the 5 M's only for big factories?

No. The 5 M's were developed for small and medium factories. In fact, they’re most valuable for small operations because they’re simple, low-cost, and don’t require high-tech tools. Many government schemes specifically target small manufacturers who follow these basics.

Do I need to use software to track the 5 M's?

No. You can track everything with paper, pens, whiteboards, and free phone apps. Many factories in rural India use handwritten logs and photos on smartphones. What matters is consistency, not tech.

Which government scheme is best for applying the 5 M's?

The Udyam Registration is the first step-it’s free and opens access to all other schemes. After that, PMKVY for worker training, TUFS for machine upgrades, and MEP for free consulting are the most relevant. All require you to show you’re following the 5 M's.

How long does it take to see results from the 5 M's?

Most factories see fewer defects and less downtime within 30 days. Productivity gains of 10-20% are common within 3 months. The key is to focus on one M at a time, not try to fix everything at once.

Can I use the 5 M's for any type of manufacturing?

Yes. Whether you make steel parts, plastic containers, textiles, or food products, the 5 M's apply. The tools might change, but the principles don’t. Manpower, machines, materials, methods, and measurement are universal.