Chemical Industry Hub Comparison Tool

When you think of chemical manufacturing in India, one name stands out above all others-Gujarat. But it’s not the whole state. It’s a single city that dominates the landscape: Jamnagar. This isn’t just a regional player. Jamnagar is the beating heart of India’s chemical industry, producing over 30% of the country’s petrochemicals and hosting some of the largest chemical plants in Asia.

Jamnagar: The Chemical Powerhouse

Jamnagar isn’t just famous for chemicals-it’s built on them. The city sits on the western coast of Gujarat, right next to the Arabian Sea, making it ideal for importing crude oil and exporting finished products. The Reliance Industries Limited (RIL) refinery here is the world’s largest petroleum refining complex. But it’s not just about oil. This refinery feeds into a massive network of chemical plants that turn crude into polymers, solvents, dyes, and specialty chemicals.

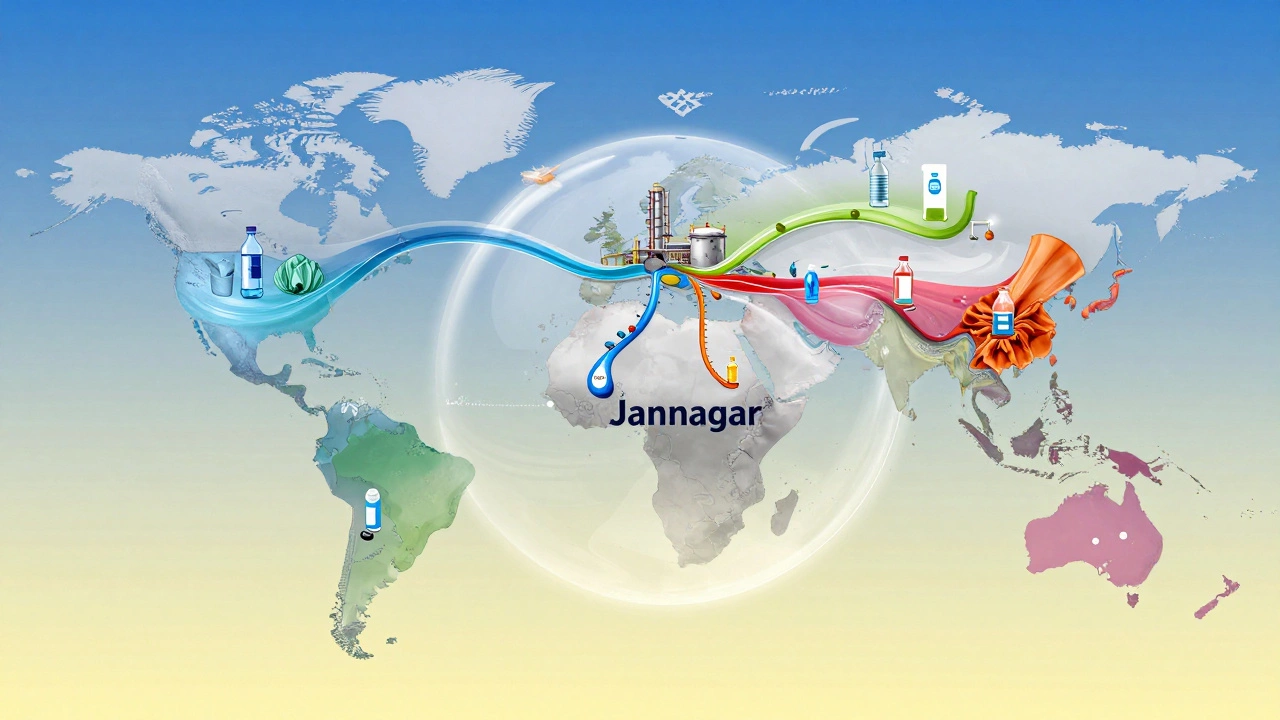

More than 150 chemical manufacturing units operate within a 50-kilometer radius of Jamnagar. These include plants making polyethylene, polypropylene, ethylene glycol, and vinyl chloride-all essential for plastics, paints, textiles, and pharmaceuticals. The city’s chemical output doesn’t just supply India. It’s exported to over 80 countries, from Southeast Asia to Europe and the Middle East.

Why Jamnagar? Location, Infrastructure, and Scale

What makes Jamnagar so special? It’s not luck. It’s strategy. The city has a dedicated port complex with deep-water berths that can handle the largest crude tankers. It has its own power grid, water treatment plants, and pipelines connecting refineries to chemical units. There’s no need to truck chemicals across the country-everything moves through underground pipelines.

The government also played a role. Gujarat’s industrial policy since the 1990s offered tax breaks, streamlined approvals, and land allocation for large-scale manufacturing. Unlike other states that focused on IT or services, Gujarat doubled down on heavy industry. By 2010, Jamnagar had become a self-contained chemical ecosystem. Today, it’s one of the few places in the world where you can go from crude oil to plastic bottles in a single integrated facility.

Other Key Chemical Hubs in India

While Jamnagar leads, it’s not alone. Other cities have carved out strong niches in chemical manufacturing:

- Vadodara (Gujarat): Home to Gujarat State Fertilizers and Chemicals (GSFC), one of India’s oldest and largest producers of ammonia, urea, and industrial chemicals. It’s a major supplier to the fertilizer and pharmaceutical sectors.

- Mumbai (Maharashtra): The historic center of India’s chemical industry. Companies like Tata Chemicals and UPL have major plants here. Mumbai’s port and legacy infrastructure still make it a hub for specialty chemicals and dyes.

- Dahej (Gujarat): A newer but rapidly growing zone. It’s part of the Dahej Special Economic Zone and hosts global players like Dow Chemical and BASF. The focus here is on high-value chemicals and advanced polymers.

- Chennai (Tamil Nadu): Known for chlor-alkali plants and chemical intermediates. Companies like LG Chem and Aarti Industries operate here, serving the electronics and pharma industries.

- Haldia (West Bengal): A major center for petrochemicals in eastern India, supported by the Haldia Petrochemicals Limited plant and its proximity to the Hooghly River for transport.

But none of these match Jamnagar’s scale. While Vadodara makes fertilizers and Mumbai makes dyes, Jamnagar makes the building blocks for almost everything else.

Who Uses These Chemicals?

The chemicals produced in Jamnagar don’t sit on shelves. They’re the hidden ingredients in everyday products:

- Plastics: Polyethylene from Jamnagar goes into grocery bags, water bottles, and packaging for food and medicines.

- Textiles: Dyes and finishing chemicals from Gujarat’s chemical plants color the clothes you wear.

- Pharmaceuticals: Active pharmaceutical ingredients (APIs) and solvents used in medicines are made here. India exports $25 billion worth of pharma products annually-much of it relies on these chemical inputs.

- Construction: PVC pipes, adhesives, and paints all come from chemical plants in Gujarat.

- Agriculture: Fertilizers and pesticides are made from chemicals produced in Vadodara and Dahej.

Without Jamnagar’s chemical output, India’s manufacturing economy would grind to a halt. Even global brands like Coca-Cola, Nestlé, and Unilever depend on these plants for packaging materials and ingredients.

Challenges and the Road Ahead

It’s not all smooth sailing. Jamnagar faces serious environmental pressures. Air and water pollution levels have been flagged by India’s Central Pollution Control Board. Local communities have raised concerns about health impacts and water scarcity. In 2023, the Gujarat government mandated that all chemical plants install real-time emission monitors and wastewater recycling systems.

Companies are responding. Reliance has invested over $2 billion in green hydrogen projects and carbon capture tech at its Jamnagar complex. Smaller players are shifting toward bio-based chemicals and circular manufacturing. The goal? To keep producing without poisoning the environment.

India’s chemical industry is projected to grow to $300 billion by 2030. Jamnagar will still be at the center of that growth-but only if it adapts. The future isn’t just about making more chemicals. It’s about making them cleaner, smarter, and more sustainable.

What’s Next for Chemical Manufacturing in India?

The government’s Production Linked Incentive (PLI) scheme for specialty chemicals is drawing new investment. Companies from South Korea, Germany, and the U.S. are setting up joint ventures in Gujarat. The focus is shifting from bulk chemicals to high-margin products like electronic-grade chemicals, lithium-ion battery materials, and biodegradable polymers.

Jamnagar is already home to India’s first commercial-scale plant making ethylene from biomass. That’s a game-changer. It means the city could one day produce chemicals without relying on imported crude oil.

For now, if you want to see where India’s chemical industry lives, you go to Jamnagar. It’s not just a city. It’s an industrial machine-one that keeps the rest of the country running.

Is Jamnagar the only city in India with a major chemical industry?

No, Jamnagar is the largest and most dominant, but other cities like Vadodara, Dahej, Mumbai, Chennai, and Haldia also have significant chemical manufacturing. Vadodara is known for fertilizers, Mumbai for dyes and specialty chemicals, and Dahej for high-value polymers. But none match Jamnagar’s scale or integration.

Which state in India has the most chemical companies?

Gujarat has the highest concentration of chemical companies in India. It accounts for nearly 40% of the country’s total chemical production. The state’s industrial policies, port access, and infrastructure have made it the top destination for both domestic and international chemical manufacturers.

Are Indian chemical manufacturers exporting globally?

Yes, India is one of the top 15 chemical exporters in the world. Jamnagar and other hubs export petrochemicals, dyes, pharmaceutical intermediates, and agrochemicals to over 100 countries. Major buyers include the U.S., China, Germany, the UAE, and Southeast Asian nations. In 2024, India’s chemical exports crossed $65 billion.

What are the biggest chemical companies in India?

Reliance Industries Limited (RIL) is the largest, with its Jamnagar complex producing over 10 million tonnes of chemicals annually. Other major players include Gujarat State Fertilizers and Chemicals (GSFC), Tata Chemicals, UPL, Aarti Industries, and LG Chem India. Many global firms like BASF, Dow, and LyondellBasell also operate large plants in India.

Is the chemical industry in India growing?

Yes, it’s growing fast. India’s chemical industry is expected to reach $300 billion by 2030, up from $170 billion in 2024. Government incentives, rising domestic demand for plastics and pharmaceuticals, and investments in green chemistry are driving this growth. Jamnagar remains the engine, but new zones in Odisha and Andhra Pradesh are emerging as future hubs.