Small Scale Industry Qualifier

Check Your Business Classification

Qualification Status

When you hear the term small scale industries, you might picture a local bakery, a workshop fixing bicycles, or a family-run textile unit. But in official terms, these aren’t just small businesses-they’re legally defined sectors with specific rules around investment, workforce, and output. Understanding which industries qualify as small scale isn’t just paperwork-it affects access to government support, loans, tax breaks, and even where you can set up shop.

What Exactly Counts as a Small Scale Industry?

In most countries, including India, the U.S., and the EU, small scale industries are defined by two main things: how much money is invested in plant and machinery, and how many people are employed. There’s no universal global standard, but the most widely used model comes from India’s Micro, Small and Medium Enterprises Development Act, which many other nations base their rules on.

For manufacturing units, a small scale industry typically means:

- Investment in plant and machinery between $100,000 and $1 million (adjusted for inflation and local currency equivalents)

- Employment of fewer than 100 workers

These numbers aren’t arbitrary. They’re set so businesses can still operate with flexibility-no big corporate bureaucracy-but still produce enough to be economically meaningful. A unit making 500 handcrafted leather bags a week qualifies. One producing 50,000 plastic containers a day using automated lines might not.

Industries Commonly Classified as Small Scale

Some sectors naturally lend themselves to small-scale operations because they rely on skilled labor, customization, or localized demand. Here are the most common ones:

- Food processing - Think pickles, spices, jams, baked goods, dairy products. These often start in home kitchens or small sheds, using local produce.

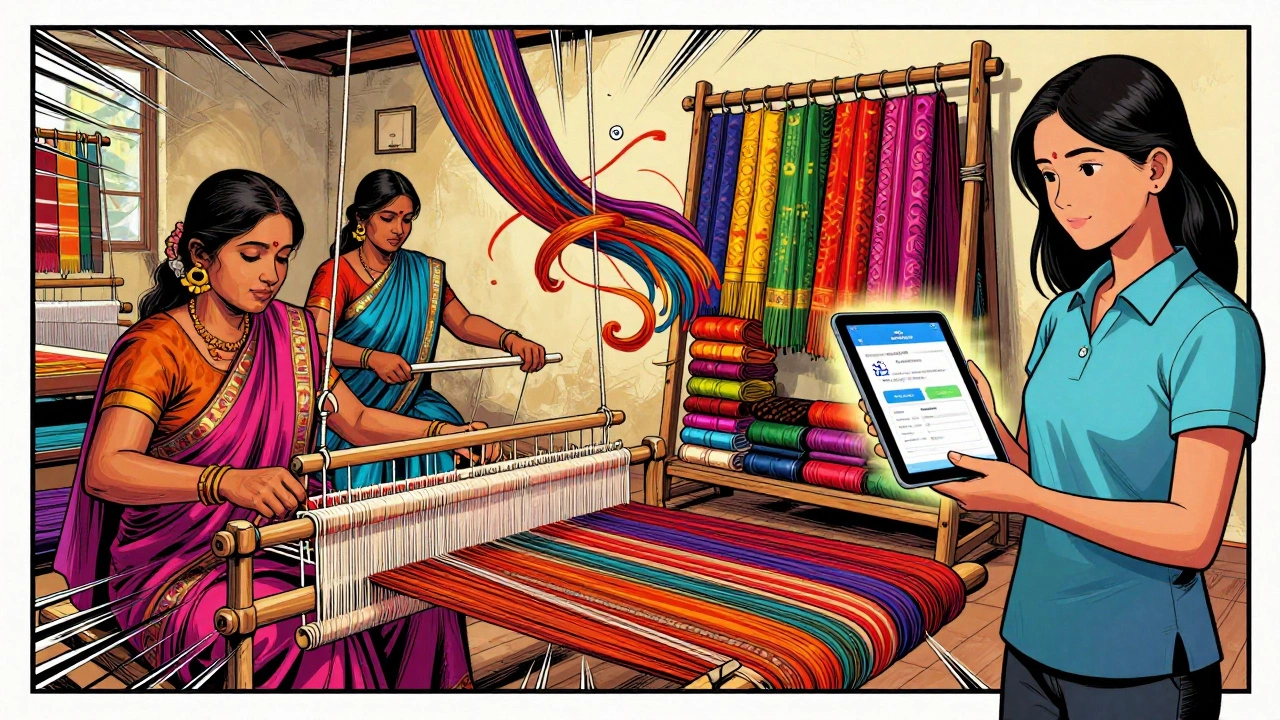

- Textile manufacturing - Handloom weaving, embroidery, stitching of garments, dyeing fabrics. These are labor-intensive and thrive in rural and semi-urban areas.

- Furniture manufacturing - Wooden chairs, tables, cabinets made by local carpenters. Many use reclaimed wood and custom designs.

- Plastic manufacturing - Small injection molding units making containers, toys, or packaging. These need minimal space and basic machinery.

- Electronics manufacturing - Assembly of simple devices like LED lights, battery chargers, or audio cables. Often done by family-run shops with soldering stations.

- Chemical manufacturing - Soaps, detergents, natural dyes, or cleaning solutions. Low-tech, low-investment, high-margin products.

- Automobile manufacturing - Not full car production. Think repair parts, custom exhausts, motorcycle accessories, or scooter modifications.

- Steel manufacturing - Small foundries making iron castings, nuts, bolts, or metal brackets. Often supply local construction or farming equipment makers.

These aren’t just hobbies-they’re serious economic engines. In India alone, small scale industries contribute over 30% of manufacturing output and employ more than 110 million people. In Nigeria, over 80% of manufacturing firms are small scale. They’re the backbone of informal economies and often the first step for entrepreneurs with limited capital.

How Governments Define Them Differently

Don’t assume the rules are the same everywhere. In the U.S., the Small Business Administration (SBA) doesn’t use investment in machinery. Instead, it defines small manufacturers by employee count: under 500 for most sectors. A workshop with 40 people making custom metal parts qualifies as small, even if it has $2 million in equipment.

In the European Union, the definition is based on turnover and balance sheet totals. A small enterprise has under €10 million in annual turnover and fewer than 50 employees. The focus here is on revenue, not machinery.

India’s system is unique because it combines both investment and employment. As of 2026, the threshold for a small manufacturing unit is up to ₹10 crore (about $1.2 million) in plant and machinery investment, with up to 100 employees. This system helps target subsidies and credit schemes more precisely.

Why the Definition Matters

Getting classified as a small scale industry isn’t about pride-it’s about survival. Here’s what it unlocks:

- Lower interest loans - Banks offer preferential rates for MSMEs. In India, the Credit Guarantee Fund Trust for Micro and Small Enterprises (CGTMSE) backs loans up to ₹5 crore without collateral.

- Tax benefits - Many countries offer reduced corporate tax rates. India’s small manufacturers pay 25% instead of 30% if turnover is under ₹400 crore.

- Government tenders - Public procurement often reserves 25% of contracts for small industries. You can’t bid unless you’re officially registered.

- Subsidies for tech upgrades - Programs like India’s Technology Upgradation Fund Scheme (TUFS) give grants for buying new machines.

- Exemptions from compliance - Fewer environmental audits, labor inspections, and reporting requirements.

Without this classification, a family-run soap-making unit might pay the same taxes as a multinational. That’s why registration with the Udyam Portal (India) or SBA (U.S.) isn’t optional-it’s essential.

What Doesn’t Count as a Small Scale Industry

Not every small business is a small scale industry. Here’s where the line gets blurry:

- Trading businesses - Buying and selling finished goods without any manufacturing? That’s retail or wholesale, not manufacturing.

- Service providers - IT consultants, graphic designers, repair shops that don’t make physical products? These fall under service-sector MSMEs, not manufacturing.

- Large factories with automation - Even if they employ only 80 people, if their machinery investment exceeds $1.5 million, they’re classified as medium or large.

- Home-based craft sellers - If you make jewelry or candles in your garage and sell online, you’re an artisan, not a registered small scale industry unless you’ve formally registered your unit and meet investment thresholds.

The key difference? Manufacturing means you’re changing raw materials into a new product. If you’re just assembling or reselling, you’re not in the manufacturing category.

How to Register Your Unit

If you’re running a small manufacturing unit, here’s how to get officially recognized:

- Get your Udyam Registration Number (India) or equivalent in your country.

- Provide details of your plant and machinery-include purchase invoices and serial numbers.

- Submit proof of employment-payroll records or employee IDs.

- Upload bank statements showing business transactions.

- Wait for approval-usually takes 2-5 working days.

Once registered, you’ll get a digital certificate. This opens doors to government tenders, export incentives, and training programs. Many small manufacturers skip this step because it feels like bureaucracy. But skipping it means leaving thousands in subsidies on the table.

Real-World Examples

Take a workshop in Coimbatore, India, that makes hand-operated flour grinders. They use 15 machines worth ₹60 lakh ($7,200), employ 18 people, and sell to rural cooperatives. That’s a textbook small scale industry.

Or a shop in Nairobi that molds recycled plastic into buckets and basins. They have five injection machines, spend $300,000 on equipment, and employ 45 workers. In Kenya, that’s still classified as small scale because the national limit is $1.5 million.

Contrast that with a factory in Guangzhou making phone cases using 20 automated presses, investing $2.1 million, and employing 80 people. Even though the workforce is small, the machinery investment pushes it into the medium category.

What’s Changing in 2026

Definitions are evolving. With automation getting cheaper, more small units are buying robots and CNC machines. Governments are adjusting thresholds upward. India raised its investment cap for small industries from ₹5 crore to ₹10 crore in 2024. The EU is considering adding environmental sustainability as a factor for classification.

Also, digital platforms are making it easier for small manufacturers to access global markets. A small textile unit in Bangladesh can now sell directly to Etsy buyers in Canada without needing a middleman. That’s shifting how we think about scale-not just size, but reach.

What hasn’t changed is the core idea: small scale industries are where innovation meets accessibility. They’re not just about survival-they’re about creating local jobs, preserving traditional skills, and building resilient economies from the ground up.

Is a home-based bakery considered a small scale industry?

Yes, if you’re producing baked goods for sale and your investment in ovens, mixers, and packaging equipment is under $1 million, and you employ fewer than 100 people. Many countries classify food processing as small scale manufacturing, even if it starts at home. You’ll need to register officially to qualify for tax benefits and government support.

Can a small scale industry upgrade to a large one?

Absolutely. As your business grows and you invest more in machinery or hire more staff, you’ll eventually cross the threshold into the medium or large category. This isn’t a failure-it’s success. Once you cross the line, you lose small-scale benefits but gain access to larger markets, formal banking, and export opportunities. Many successful manufacturers plan for this transition from day one.

Do small scale industries need environmental permits?

It depends. In most countries, small scale manufacturing units are exempt from full environmental impact assessments-but they still need basic waste and emission controls. For example, a soap-making unit must handle chemical runoff properly. A plastic molding unit must dispose of scraps legally. Local authorities usually provide simplified compliance checklists for small units.

Can I start a small scale industry with no prior experience?

Yes. Many governments offer free training programs, mentorship, and even seed funding for first-time entrepreneurs in small scale manufacturing. Look for local industry associations, startup incubators, or government skill development missions. Starting small-with one machine and one product-is better than waiting for the perfect plan.

Are small scale industries profitable?

Many are. Profit margins vary by industry: food processing can be 20-40%, textiles 15-30%, and electronics assembly 10-25%. The key is low overhead, local sourcing, and direct sales. A small unit making custom wooden furniture can earn more per unit than a mass producer because they avoid retail markups and shipping costs. Scale doesn’t always mean profit-focus on value, not volume.