Manufacturing Incentive Calculator

Calculate Your Potential Incentive Benefits

Enter your details above to see potential government incentives for your manufacturing business.

Results will appear here based on your inputs.

When you hear the word manufacturing, you probably think of factories, robots, assembly lines, and workers putting things together. But behind every bolt tightened and every product shipped, there’s a much bigger system at work-one shaped by rules, money, and people you never see. So who’s really in charge of manufacturing? Is it the factory owner? The CEO? Or does the government hold the keys?

Manufacturing Doesn’t Run Itself-Someone Has to Set the Rules

Let’s cut through the noise: no factory operates in a vacuum. Even the most private, family-run workshop has to follow laws. Safety standards. Environmental limits. Labor rules. Tax codes. Import tariffs. These aren’t suggestions. They’re legal requirements. And who writes them? Governments-at local, state, and national levels.

In countries like India, China, Germany, and the United States, manufacturing is heavily guided by national schemes designed to boost output, create jobs, and protect domestic industries. In India, for example, the Production Linked Incentive (PLI) Scheme gives cash bonuses to companies that make electronics, pharmaceuticals, or solar panels locally. If a company increases its output by 20% over three years, it gets a percentage of its sales back as a payout. That’s not just encouragement-it’s a financial lever pulled by the government to steer production where it wants it.

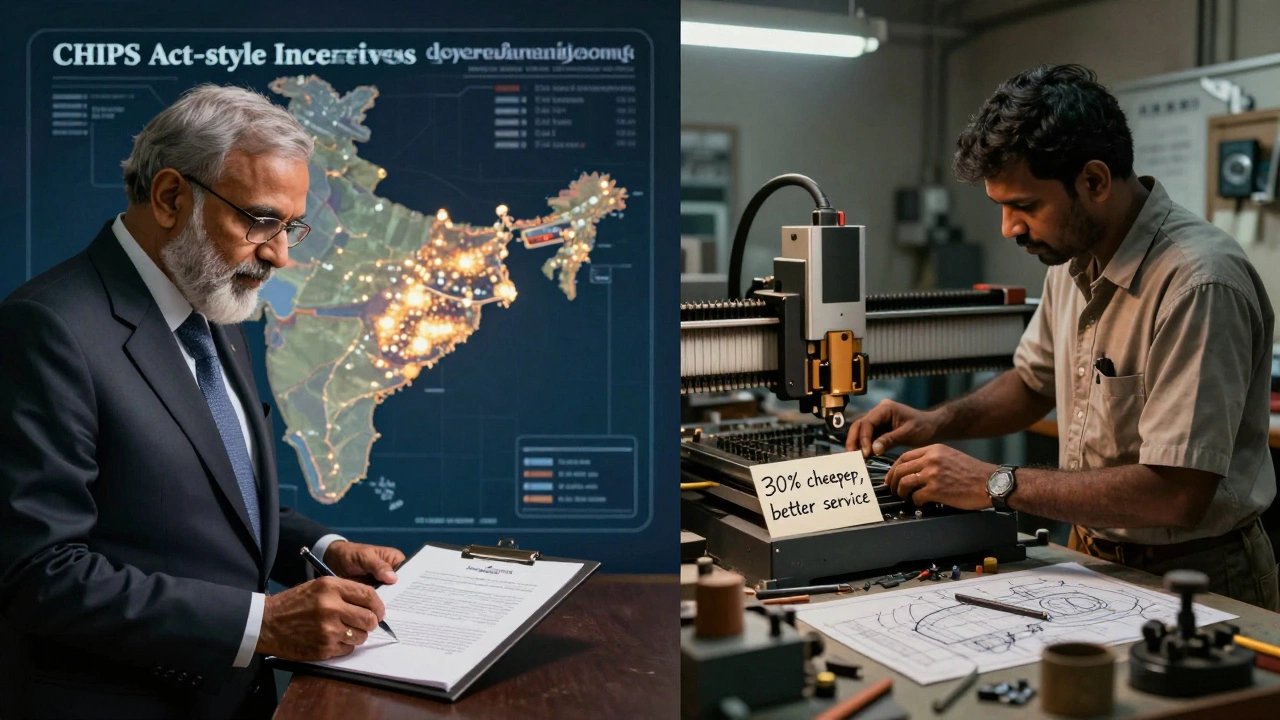

In the U.S., the CHIPS and Science Act poured over $52 billion into semiconductor manufacturing. Why? Because chips are critical for cars, phones, and defense systems. The government didn’t just hand out grants-it set conditions: companies had to build plants in the U.S., hire local workers, and avoid expanding production in China for ten years. That’s not just funding. That’s control.

Who Actually Makes the Decisions on the Ground?

Yes, governments set the rules. But day-to-day? That’s the factory manager, the plant supervisor, the procurement team. They decide which machines to buy, when to run shifts, who to hire, and which suppliers to trust. They’re the ones who actually turn policy into product.

Take a small auto parts maker in Tamil Nadu, India. They got $1.2 million from the PLI scheme to upgrade their CNC machines. But the owner still had to choose between German and Taiwanese equipment. He picked the Taiwanese option because it was 30% cheaper and came with better local service. The government didn’t tell him which brand to buy. He did. The scheme created the opportunity. He made the call.

Same in Wisconsin. A family-owned metal stamping plant got a $3 million grant under the CHIPS Act to retool for electric vehicle parts. But they had to train 40 new workers in robotics programming. Who trained them? The plant’s own engineers, using a curriculum they built with help from a community college-not the Department of Commerce.

So here’s the real answer: governments set the playing field. They offer money, rules, and incentives. But the people running the factory? They’re the ones who decide how to play the game.

Government Schemes Are Tools, Not Magic Wands

Not every government manufacturing scheme works. Some fail because they’re too vague. Others collapse because they don’t match local realities.

In 2020, Brazil launched a program to boost domestic appliance manufacturing. They offered tax breaks to companies that used 70% local parts. Sounds smart, right? But local suppliers couldn’t make the quality parts needed. Companies ended up importing more than before just to meet demand. The scheme backfired.

Compare that to Vietnam’s success with electronics. Their government didn’t just give money. They built industrial parks with power, water, and roads already in place. They trained workers in assembly line skills. They cut red tape for foreign investors. Result? Samsung, Intel, and Apple now make half their phones and laptops there.

The difference? Vietnam didn’t just hand out cash. They built an ecosystem. They understood that manufacturing isn’t just about machines-it’s about logistics, skills, and supply chains.

Who’s Responsible When Things Go Wrong?

When a factory pollutes a river, who gets blamed? The owner? The government that didn’t enforce cleanup rules? Or both?

In 2023, a chemical plant in Gujarat, India, leaked toxic waste into a nearby river. The company was fined. The local environmental agency was criticized. But the real failure? A government scheme that prioritized job creation over environmental checks. The plant got tax breaks and fast-tracked permits-without proper pollution controls.

That’s the trade-off. Governments want growth. They want exports. They want jobs. But if they cut corners on safety, environment, or labor rights to get there, the cost shows up later-in health bills, cleanups, and lost trust.

On the flip side, Germany’s Industrie 4.0 program pushes automation and green tech in manufacturing. It doesn’t just fund machines-it funds worker retraining. Factories that adopt AI-driven quality control get subsidies-but only if they also teach their workers how to use it. That’s responsibility built into the system.

Small Manufacturers Don’t Get a Seat at the Table-Until They Do

Big companies get the headlines. But 90% of manufacturers worldwide are small or medium-sized. They don’t have lobbyists. They don’t have legal teams. They’re often left out of policy talks.

That’s changing. In Mexico, the government launched a program called Manufactura 4.0 to help small workshops adopt digital tools. Instead of giving grants to big firms, they partnered with local technical schools. Every small factory that enrolled got free access to training, software licenses, and a mentor. Within two years, 800 small shops increased output by 40% on average.

Why did it work? Because the government didn’t assume small makers needed the same help as big ones. They listened. They adapted. They gave them tools, not just money.

Compare that to a failed program in Nigeria, where the government gave $10,000 grants to 500 small manufacturers. No training. No follow-up. Half the businesses used the money to buy generators or pay off debts. Only 12% actually improved production. The scheme didn’t fail because of corruption-it failed because it didn’t understand the real needs of the people it was trying to help.

Who’s Really in Charge? It’s a Team Sport

No single person or agency controls manufacturing. It’s a chain:

- Government sets the rules, offers incentives, builds infrastructure, and enforces standards.

- Industry associations lobby for better policies and share best practices.

- Factory owners decide what to make, how to make it, and who to hire.

- Workers bring the skills, the sweat, and the problem-solving.

- Suppliers deliver the raw materials and parts that keep the lines moving.

Change one link, and the whole chain shifts. If the government raises tariffs on imported steel, factories might switch to local suppliers-or move production overseas. If workers demand higher wages, automation speeds up. If a supplier goes bankrupt, production halts.

So who’s in charge? The answer isn’t one person. It’s a system. And the most effective systems? They don’t just control-they connect. They listen. They adapt.

What Happens When Government Pulls Back?

When governments stop supporting manufacturing, the effects aren’t immediate-but they’re deep.

Look at the U.S. Rust Belt. In the 1980s and 90s, federal support for steel and auto manufacturing faded. Tax breaks disappeared. Training programs were cut. Factories closed. Towns collapsed. It took decades to rebuild. And even now, many areas still haven’t recovered.

Contrast that with South Korea. In the 1970s, they invested heavily in shipbuilding and electronics. They didn’t just fund companies-they built research centers, trained engineers, and forced local banks to lend to manufacturers. Today, Hyundai and Samsung are global giants. That wasn’t luck. It was deliberate, long-term policy.

Manufacturing doesn’t grow on its own. It needs oxygen: stable rules, skilled labor, reliable supply chains, and consistent support. Governments provide that oxygen. But they can’t breathe for the factory.

Final Answer: It’s Shared Responsibility

So who’s in charge of manufacturing? The government sets the stage. The factory runs the show. The workers make it happen. The suppliers keep it fed. The customers decide what’s worth making.

Blaming the government for a failed factory? Too simple. Blaming the factory owner for not growing? Also incomplete. The truth is, manufacturing thrives-or dies-because of how well all these pieces work together.

The best systems don’t try to control every detail. They create the conditions where innovation, skill, and investment can grow. That’s not micromanagement. That’s leadership.

If you’re running a factory, know the rules. Use the grants. But don’t wait for someone else to fix your problems. If you want to grow, you’ve got to act-within the system, but with your own vision.

If you’re a policymaker, stop handing out money and start building ecosystems. Train people. Fix roads. Simplify permits. Support small players. Don’t just want more factories-want better ones.

Manufacturing isn’t owned by one person. It’s built by many. And it only works when everyone does their part.

Who is legally responsible for safety in a manufacturing plant?

The factory owner or operator is legally responsible for day-to-day safety. But governments set and enforce the standards-like OSHA in the U.S. or the Health and Safety Executive in the UK. If a plant violates safety rules, the government can fine, shut down, or even press criminal charges. Both parties share responsibility: one runs the plant, the other holds the leash.

Can small businesses benefit from government manufacturing schemes?

Yes, but only if the scheme is designed for them. Many programs target big firms because they’re easier to track. But countries like Mexico, India, and Vietnam now have separate tracks for small manufacturers-offering training, access to shared equipment, and simplified paperwork. The key is looking for programs labeled "MSME," "small industry," or "local manufacturing support." Don’t assume you’re too small-you’re often exactly who these programs need.

Do government manufacturing schemes actually create jobs?

They can, but not always. A 2024 study by the World Bank analyzed 12 major manufacturing incentive programs across developing countries. Only 5 of them led to net job growth. The rest just shifted jobs from one company to another-or replaced workers with machines. The programs that worked most often combined cash incentives with mandatory hiring targets and worker training. Money alone doesn’t create jobs. People do.

How do I find government manufacturing grants in my country?

Start with your national ministry of industry or commerce. Look for terms like "industrial policy," "manufacturing incentives," or "technology adoption grants." In the U.S., check the Department of Commerce’s Economic Development Administration. In India, visit the Department for Promotion of Industry and Internal Trade (DPIIT). In the EU, search the European Innovation Council. Local chambers of commerce often have guides too. Don’t wait for ads-most grants require proactive applications.

What’s the biggest mistake manufacturers make with government schemes?

Treating grants as free money. Many companies apply for funding without understanding the conditions. They might get $500,000 to buy new equipment-but have to prove they increased output by 25% over three years. If they don’t, they have to pay it back. Others spend the money on repairs or payroll instead of the approved use. The best manufacturers treat grants like investments: they plan, track, measure, and report. It’s not a handout. It’s a partnership.