Pittsburgh Steel: What It Is, Why It Matters, and How It Connects to Global Manufacturing

When people talk about Pittsburgh steel, the high-quality carbon steel produced in Pennsylvania during the 20th century’s industrial boom. Also known as American steel, it was the backbone of bridges, skyscrapers, and railroads across the U.S. This wasn’t just metal—it was the material that built a nation’s infrastructure. Pittsburgh didn’t just make steel; it defined what good steel looked like: strong, consistent, and made with precision.

That legacy still echoes today, even as production shifted. The Gary Works, the largest steel mill in the United States, located in Indiana, now dwarfs Pittsburgh’s old mills in output. But Gary Works didn’t replace Pittsburgh’s reputation—it inherited it. Both are part of the same story: American steel at its peak. And while India now manufactures smartphones, solar inverters, and EV electronics, the raw materials still trace back to these foundational systems. The same principles that made Pittsburgh steel reliable—quality control, skilled labor, and integrated supply chains—are now what Indian factories need to compete globally.

Steel isn’t just about volume. It’s about trust. When a manufacturer in Chennai picks a supplier, they don’t just ask for price. They ask: Can this steel hold up under stress? Will it last? Those questions were first answered in Pittsburgh’s blast furnaces. Today, Indian manufacturers use similar metrics to evaluate their own inputs, whether it’s steel for machinery or alloys for electronics housings. The steel manufacturing, the process of turning iron ore into usable metal through smelting, refining, and rolling hasn’t changed much in basics—it’s just faster, cleaner, and more automated now.

What’s surprising is how little attention India pays to this history. We talk about Make in India, export numbers, and government schemes. But we rarely look back at the original models that made global manufacturing possible. Pittsburgh didn’t win because of subsidies. It won because it mastered the 5 M’s of manufacturing: Manpower, Machines, Materials, Methods, and Measurement. The same framework now helps small factories in Tamil Nadu qualify for subsidies. The same discipline helps a startup in Bangalore pitch to a manufacturer.

There’s a reason why the biggest steel plant in the U.S. is in Gary, not Pittsburgh. Industries move. But the standards don’t. The steel that built the Eiffel Tower’s support beams, the Brooklyn Bridge, and the first transcontinental rail lines still sets the bar. Today’s manufacturers in India don’t need to make steel in Pittsburgh. But they do need to understand what made it matter. That’s the real lesson.

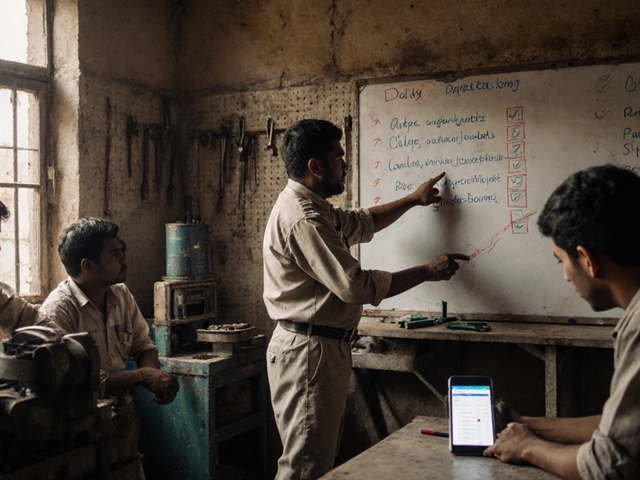

Below, you’ll find real stories from Indian manufacturing—how startups secure funding, how factories cut costs, how exporters beat global rivals. None of them mention Pittsburgh. But every one of them is built on the same foundation: precision, persistence, and the quiet understanding that great manufacturing doesn’t happen by accident. It’s made, one batch at a time, just like Pittsburgh steel once was.