Plastic Waste: How India’s Manufacturing Industry Is Tackling the Crisis

When we talk about plastic waste, the discarded plastic materials that overwhelm landfills and waterways, often from packaging, electronics, and consumer goods. Also known as synthetic waste, it’s one of the fastest-growing environmental problems in India, with over 10,000 tons generated daily. This isn’t just trash—it’s a byproduct of how we make things. Every smartphone case, every food container, every wire insulator made in India leaves behind plastic that doesn’t break down. And while we blame consumers, the real story starts in factories.

plastic manufacturing, the industrial process of turning raw polymers into everyday products like bottles, boxes, and electronic housings is booming in India. Companies are producing more than ever, thanks to Make in India and export demand. But here’s the catch: most of these manufacturers don’t control what happens after the product leaves the plant. That’s where recycling India, the growing network of informal collectors, sorting centers, and formal recyclers turning waste into raw material comes in. Right now, only 30% of plastic waste gets recycled. The rest ends up in rivers, fields, or open dumps. But that’s starting to change. Some factories now design products for easy disassembly. Others partner with local recyclers to take back used packaging. A few even use recycled plastic as feedstock—cutting costs and reducing new plastic use.

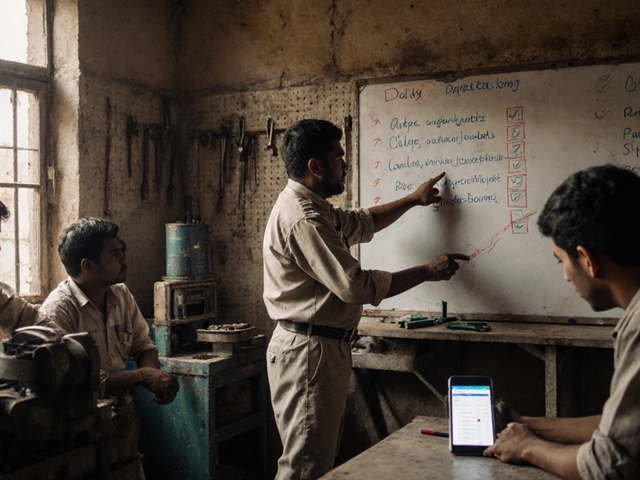

It’s not just about cleaning up. It’s about redesigning. The manufacturing sustainability, the shift toward reducing environmental harm in production through material choices, energy use, and waste recovery movement is quietly reshaping how small and big factories operate. Think of it like this: if you’re making medical devices or solar inverters—products that need to be clean, safe, and reliable—you can’t ignore where your plastic comes from. Buyers are asking. Regulators are watching. And the cost of ignoring plastic waste? It’s rising fast—in fines, reputational damage, and lost contracts.

What you’ll find in the posts below aren’t just reports on pollution. They’re real stories from Indian factories that are cutting plastic waste at the source. From startups using recycled pellets to make phone cases, to big players redesigning packaging to use 40% less plastic, these are the people making change happen. You’ll see how government schemes help, how profit margins shift when you recycle, and why the next big opportunity in manufacturing isn’t just making more—it’s making less waste.