5 M's of Manufacturing: What They Are and How They Drive Real Production

When you hear 5 M's of manufacturing, a foundational framework used to analyze and improve production systems. Also known as Man, Machine, Material, Method, and Measurement, it's the quiet backbone of every factory that actually delivers quality products on time. This isn’t theory—it’s what shop floor managers check every morning before shift starts. If one of these five elements is off, the whole line slows down. You can have the best machine in the world, but if your workers aren’t trained, your materials are late, or you’re not measuring output correctly, you’re losing money.

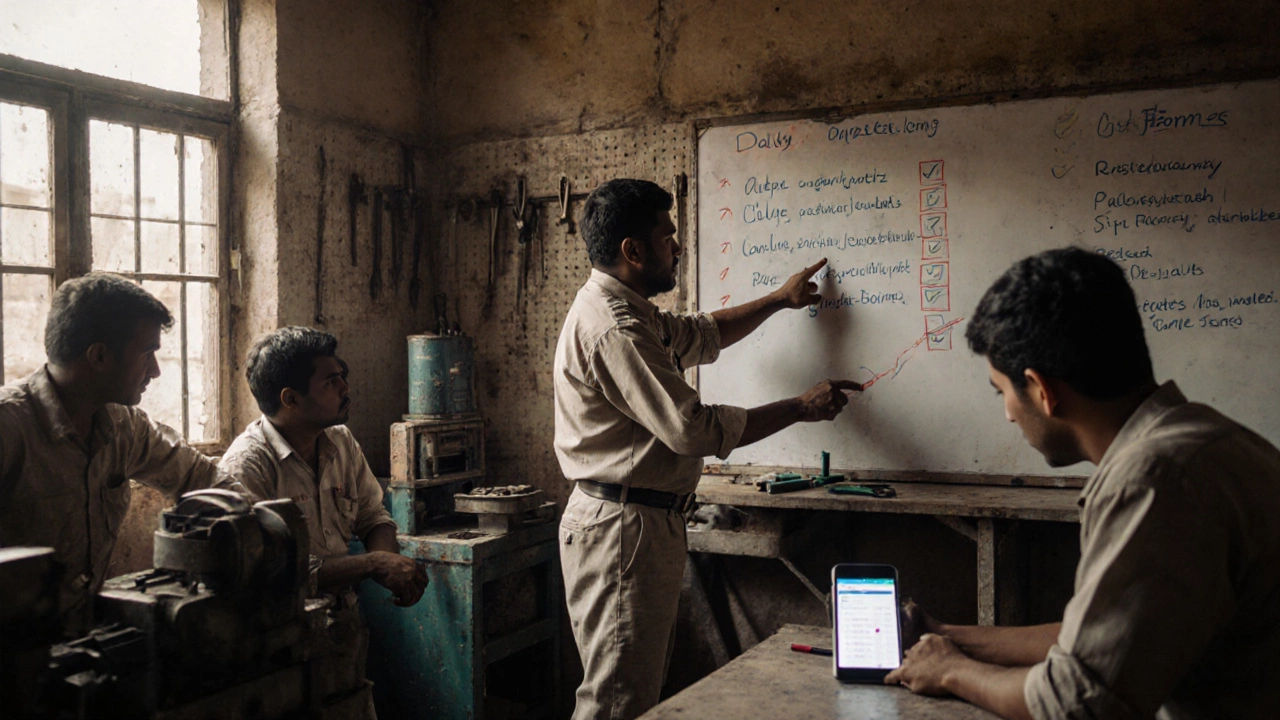

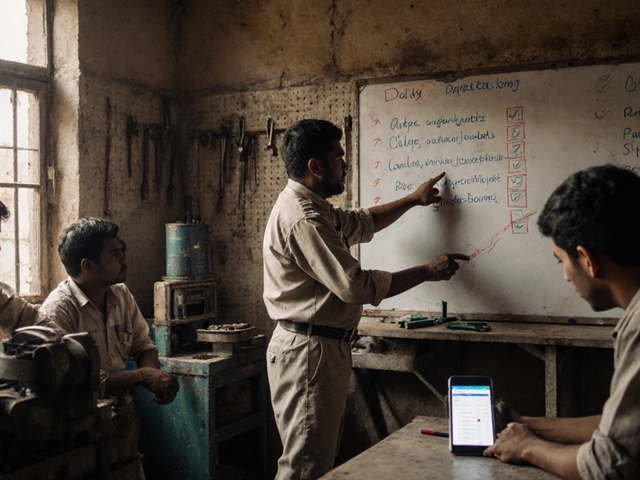

The Man, the human element in production—from operators to supervisors is often the most overlooked. A skilled worker can compensate for a slightly outdated machine. A poorly trained one can wreck even the most advanced system. Then there’s Machine, the tools, robots, and equipment that turn inputs into outputs. In India, many small manufacturers still rely on older CNC machines or manual presses, but even these can be optimized if maintained and used correctly. Material, the raw inputs like plastic pellets, copper wire, or fabric rolls must be consistent. A batch of faulty connectors can shut down an entire electronics assembly line. Method, the step-by-step process that defines how something is made is where most inefficiencies hide. It’s not about having the fanciest workflow—it’s about having a repeatable, documented one. And finally, Measurement, tracking output, defects, cycle times, and downtime. You can’t improve what you don’t measure. That’s why startups that track even basic metrics outperform those that guess.

These five aren’t just checklist items—they’re connected. A change in material affects the method. A new machine changes the skill set needed for Man. Measurement reveals where the bottleneck is, and that tells you where to fix Machine or Method. The posts below don’t talk about the 5 M’s in isolation. They show them in action: how a small electronics maker in Tamil Nadu improved output by retraining staff (Man), how a food processor cut waste by switching raw material suppliers (Material), how a startup used simple measurement tools to secure funding by proving their process (Method), and why even the best machine fails without proper maintenance (Machine). You’ll find real examples from Indian factories, not textbook definitions. What you’ll see here isn’t about big corporations with six-figure budgets. It’s about small shops, local makers, and first-time founders who cracked production by getting these five right—one step at a time.