Daily Revenue in Manufacturing: What It Really Takes to Profit

When you hear daily revenue, the total money a manufacturing business brings in each day from selling its products. Also known as daily sales income, it's not just about how much you sell—it's about what’s left after everything else is paid. Most small manufacturers think high volume means high profit. But that’s not true. You can sell 500 units a day and still lose money if your costs are out of control. Daily revenue only matters when you know how much of it actually ends up in your pocket.

That’s where manufacturing profit, the money left after subtracting all production costs from daily revenue. Also known as net manufacturing income, it’s the real measure of whether your factory is working or just spinning wheels. A small manufacturer making phone cases might bring in ₹50,000 a day in revenue—but if raw materials, labor, and electricity cost ₹42,000, your profit is just ₹8,000. That’s a 16% margin. In food processing or electronics assembly, margins can be as low as 5% or as high as 40%, depending on scale, location, and efficiency. The difference isn’t luck—it’s how well you track the manufacturing costs, all expenses tied to turning raw materials into finished goods, including labor, energy, tools, and overhead. Also known as production expenses, it’s the backbone of every financial decision..

Think about it: if you don’t measure your daily revenue against your costs, you’re flying blind. You might think you’re growing because you’re selling more, but if your costs are rising faster, you’re actually shrinking. That’s why the best small manufacturers check their numbers every morning—not just sales, but what each product actually cost to make. They know that one machine breakdown, one delayed shipment, or one spike in electricity rates can wipe out a week’s profit.

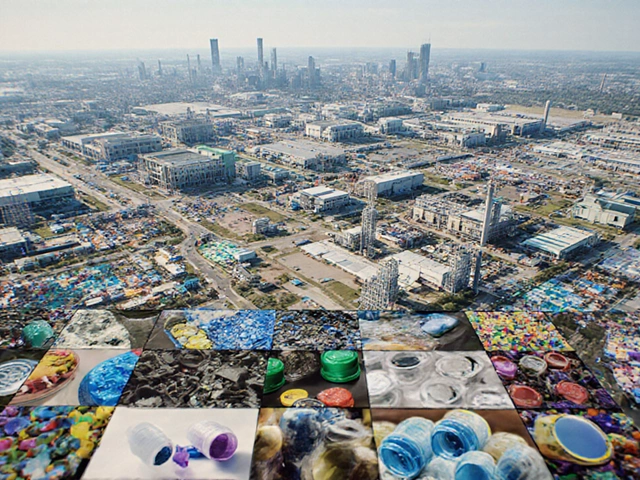

And it’s not just about cutting costs. It’s about smart pricing, lean processes, and knowing exactly which products earn the most. A factory making medical devices might have lower daily revenue than one making plastic toys, but higher profit because the cost to make each unit is much lower. That’s the power of understanding your numbers. You don’t need to be big to be profitable—you just need to be sharp.

The posts below show you exactly how real manufacturers in India are tracking daily revenue, what they’re cutting, what they’re keeping, and how they’re turning small daily gains into long-term success. You’ll see real profit margins from food processing, electronics, and chemical manufacturing. You’ll learn how small factories use the 5 M’s and 5 Ps to boost daily output without hiring more people. And you’ll find out why some manufacturers make ₹20,000 a day and live comfortably, while others make ₹2 lakh and still struggle to pay their bills. This isn’t theory. It’s what’s happening right now in workshops and factories across the country.