Import Sources for Indian Manufacturing: Where Materials Come From

When you think about manufacturing in India, you might picture factories in Tamil Nadu or Gujarat—but what’s actually going into those factories? Import sources, the origins of materials and components used in Indian production. Also known as supply chain origins, these are the critical links that keep Indian factories running—from the rare earth metals in smartphone screens to the plastic pellets used in medical devices. Without reliable import sources, even the best-designed products can’t be made. India doesn’t make everything itself, and that’s not a weakness—it’s a strategic reality. The country imports over $500 billion in goods annually, and a huge chunk of that feeds directly into manufacturing.

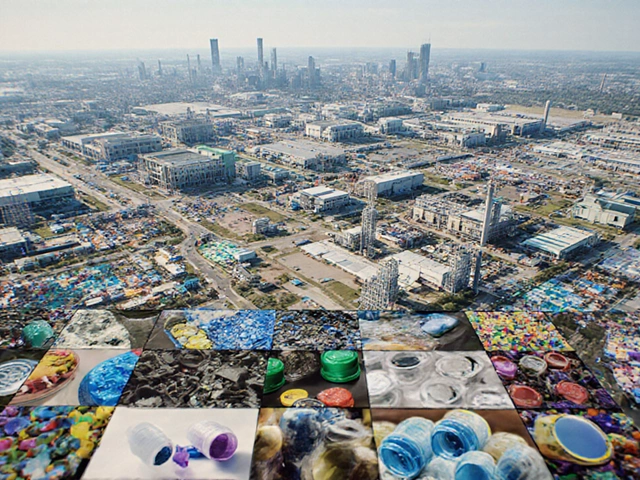

Let’s break down where the most important materials come from. For electronics, semiconductors, the tiny chips powering everything from phones to solar inverters. Also known as integrated circuits, they’re mostly imported from Taiwan, South Korea, and the United States. The same goes for lithium-ion batteries—over 80% of the cells used in Indian EVs and power backups come from China. Even plastic resins, which go into everything from toys to medical tubes, are largely sourced from the Middle East and Southeast Asia. For chemicals, India relies on imports from Germany, Japan, and the U.S. for specialty compounds used in pharmaceuticals and dyes. And textiles? Cotton is homegrown, but synthetic fibers like polyester and nylon? Mostly imported from China and Saudi Arabia.

Why does this matter? Because your product’s cost, quality, and delivery time all depend on where your inputs come from. A delay at the Port of Mundra or a tariff hike in the U.S. can ripple through a small factory in Pune. That’s why smart manufacturers don’t just look at price—they track geopolitical risks, shipping lanes, and supplier reliability. The supply chain India, the network of global and local suppliers feeding Indian production. Also known as manufacturing logistics, it’s not just about moving boxes—it’s about managing risk, timing, and quality control across continents. Some companies are starting to shift toward regional sourcing—like buying PCBs from Vietnam instead of China—to reduce dependency. Others are working with Indian suppliers to build local alternatives, especially for packaging and basic components.

What you’ll find in the posts below isn’t theory—it’s real data. You’ll see which Indian states import the most electronics, who the top exporters are, and how small manufacturers are adapting when global supply chains shake. There’s no fluff, no marketing spin. Just straight facts on where materials come from, how costs add up, and what’s changing fast. Whether you’re running a small workshop or planning your next product line, understanding import sources isn’t optional—it’s the foundation of every successful manufacturing decision in India today.