India pharmaceutical industry: Key players, manufacturing, and what’s really driving growth

When we talk about the India pharmaceutical industry, a globally significant sector known for producing low-cost generic drugs and supplying over 60% of the world’s vaccines. Also known as Indian drug manufacturing, it’s not just about cheap pills—it’s a complex ecosystem of family-run giants, government policies, and high-tech production units that keep millions alive worldwide.

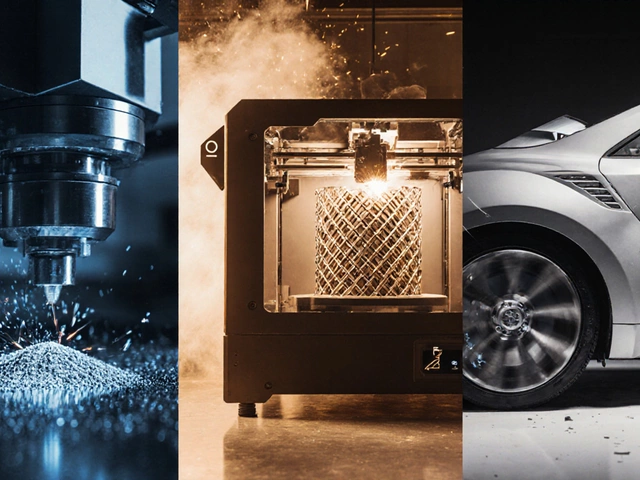

The Cipla, a major Indian pharmaceutical company founded in 1935 and still controlled by the Hamied family. Also known as Cipla India pharma, it’s one of the few global pharma leaders that refused buyouts to stay focused on affordable medicine isn’t an outlier—it’s a model. Many of India’s top drug makers are still privately held, family-owned businesses that prioritize long-term impact over quick profits. This contrasts sharply with Western pharma, where shareholders often demand quarterly growth. The pharma manufacturing India, the backbone of the country’s drug supply chain, involving everything from API production to finished dosage units in licensed facilities. Also known as Indian drug production, it’s supported by over 3,000 licensed plants and strict compliance with WHO-GMP standards has grown into one of the most efficient in the world. You won’t find massive corporate labs everywhere—many are medium-sized factories run by engineers who know exactly how to cut waste and scale quality without raising prices.

What makes this industry tick? It’s not just low labor costs. It’s deep expertise in chemical synthesis, decades of experience copying and improving foreign patents, and a government that’s pushed export incentives hard. India now supplies 20% of all generic drugs to the U.S. and over 50% of its vaccine needs. The Indian drug makers, a diverse group ranging from Cipla and Sun Pharma to hundreds of small-scale producers supplying local clinics. Also known as India pharma companies, they operate with lean teams and high output, often using the same 5 M’s of manufacturing that small electronics factories rely on are quietly reshaping global health. And while global giants try to buy them out, most Indian pharma families still hold the reins—because they believe medicine shouldn’t be a luxury.

If you’re wondering how India keeps making life-saving drugs so cheaply, the answer is in the details: batch processing units that run 24/7, strict raw material sourcing from local chemical suppliers, and a workforce trained for precision, not just speed. You’ll find posts here that break down who owns Cipla, how drug manufacturing units are classified, what’s really exported, and why this industry will keep growing—even if the world tries to shut it out. This isn’t theory. It’s real factories, real people, and real medicine made in India.