Plastic Supplier: How to Find Reliable Partners for Indian Manufacturing

When you're building a product in India, your plastic supplier, a company that provides raw plastic materials or molded components for manufacturing. Also known as plastic material vendor, it plays a silent but critical role in everything from phone cases to medical devices. Too many startups pick the cheapest option and end up with brittle parts, delayed shipments, or products that fail inspections. A good plastic supplier doesn’t just send plastic—they solve problems before they happen.

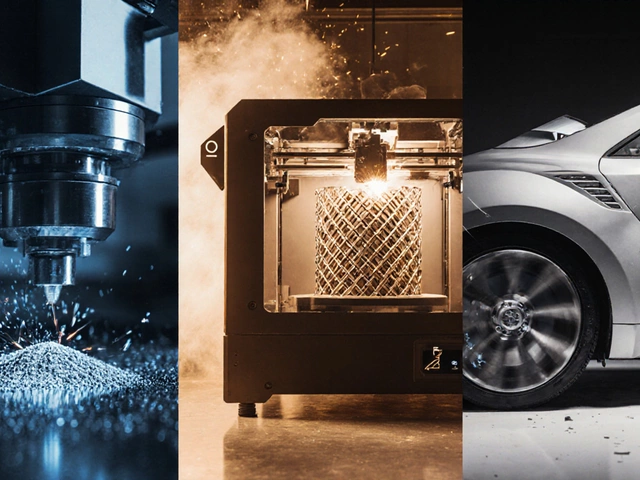

The Indian plastic industry is huge, but not all players are equal. You’ll find suppliers in Gujarat making pellets, Tamil Nadu producing custom injection-molded parts, and Maharashtra handling high-volume extrusion. The best ones work with plastic manufacturing companies, firms that turn raw plastic into finished components using molds, presses, and automated lines. These manufacturers know which resins—like ABS, HDPE, or PC—work for your product’s temperature, strength, and UV exposure needs. They also understand India’s plastic industry, the ecosystem of resin producers, recyclers, mold makers, and logistics providers that support plastic production nationwide. If your supplier can’t explain the difference between virgin and recycled HDPE, walk away.

Don’t assume all suppliers are the same. Some specialize in food-grade materials for packaging. Others focus on automotive-grade polymers that withstand engine heat. A few even offer design help—helping you tweak your part to reduce material use or avoid warping. The top ones in India have ISO certifications, test reports on file, and can show you samples from actual production runs, not just catalog photos. They also know local regulations like BIS standards and plastic waste rules that could delay your shipment.

What you’re really looking for is a partner, not a vendor. The right plastic supplier will answer your calls, send samples fast, and warn you if your design is going to cost more than it should. They’ll tell you if a cheaper material will crack in monsoon humidity or if a different mold design could cut your per-unit cost by 20%. These aren’t just technical details—they’re profit margins.

Below, you’ll find real examples of companies that got this right, stories from manufacturers who avoided costly mistakes, and checklists to help you vet suppliers before signing anything. No fluff. Just what works in India’s manufacturing landscape today.