Waste Reduction in Manufacturing: How Indian Factories Are Cutting Waste and Boosting Profit

When we talk about waste reduction, the practice of minimizing unused materials, energy, and time in production. Also known as resource optimization, it’s not about being green for the sake of it—it’s about making more with less, and keeping more profit in your pocket. In Indian manufacturing, where margins are tight and raw material costs keep rising, cutting waste isn’t optional. It’s the difference between surviving and thriving.

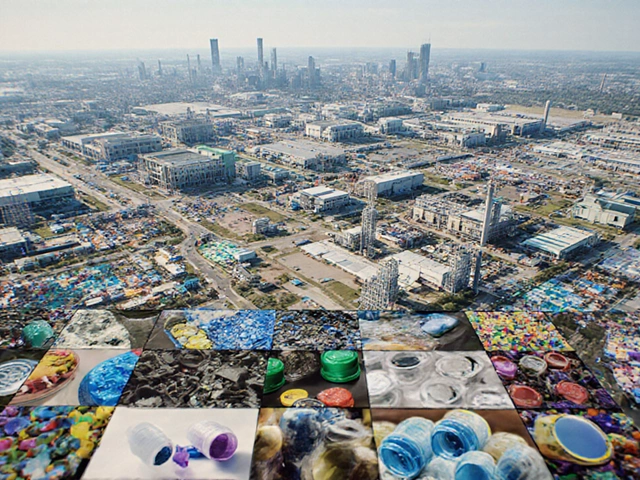

Think about it: if a factory throws away 15% of its plastic or metal every day, that’s not just trash—it’s cash walking out the door. The best manufacturers don’t just recycle scraps; they redesign processes to avoid waste before it happens. This is where lean manufacturing, a system focused on eliminating inefficiency and maximizing value comes in. It’s not a fancy term—it’s a daily habit: fixing overproduction, reducing idle machines, stopping over-processing, and cutting down on unnecessary movement. You see this in small workshops in Tamil Nadu that now use scrap metal shavings to make new parts, or in food processing units in Gujarat that repurpose leftover pulp into animal feed. These aren’t big corporations with billion-dollar budgets—they’re local makers who figured out that waste reduction starts with asking one simple question: "Do we really need to do it this way?"

And it’s not just about materials. industrial efficiency, how well a factory turns inputs into finished goods without waste includes time, energy, and labor. A machine running idle for hours? That’s waste. Workers walking ten minutes to get a tool? That’s waste. Overproducing 500 units when only 300 are ordered? That’s waste too. The posts below show real examples—factories that cut waste by retraining staff, using simple measurement tools from the 5 M’s of manufacturing, or switching to just-in-time material delivery. You’ll see how small changes in how they handle materials, schedule shifts, or track output led to 20%, 30%, even 50% less waste. No magic tech. No huge investments. Just smarter habits.

What you’ll find here aren’t theory-heavy guides. These are real stories from Indian factories—some tiny, some growing fast—where waste reduction turned into higher profits, faster delivery, and happier workers. Whether you run a small electronics assembly line, a plastic molding shop, or a food processing unit, the lessons here apply. Because in manufacturing, the best way to grow isn’t always to make more. Sometimes, it’s to make less waste.