Cheapest Manufacturing: How to Cut Costs Without Losing Quality

When you hear cheapest manufacturing, the process of producing goods at the lowest possible cost while maintaining acceptable quality. Also known as low cost manufacturing, it’s not about cutting corners—it’s about working smarter. In India, this means using local materials, skilled labor, and government incentives to build products that compete globally without the high price tag.

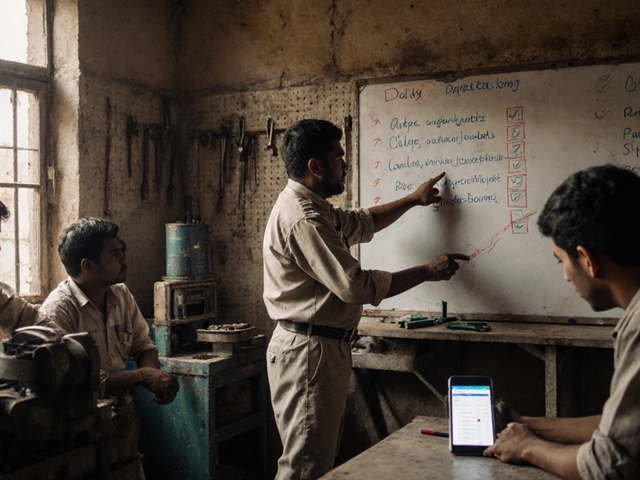

Small scale manufacturing, businesses that produce in smaller batches with limited automation. Also known as local maker operations, these are often the real winners in cheapest manufacturing. They avoid massive overhead, rely on hand-assembled processes, and build direct relationships with customers. Think of a workshop in Tamil Nadu making solar inverters using locally sourced circuit boards, or a family-run factory in Uttar Pradesh producing medical devices with basic but precise tools. These aren’t factories with robots—they’re lean, focused, and deeply efficient. And they’re not alone. India’s manufacturing in India, the growing ecosystem of factories, suppliers, and policy support driving domestic production. Also known as Make in India, it’s backed by tax breaks, duty exemptions, and training programs that help small players slash costs without sacrificing standards. The government doesn’t just hand out money—it creates systems that let you do more with less. A small electronics maker can qualify for subsidies just by following the 5 M’s of manufacturing: Manpower, Machines, Materials, Methods, and Measurement. That’s not fluff—it’s a checklist that cuts waste before it starts.

What makes cheapest manufacturing work isn’t cheap labor alone. It’s the smart use of materials. Many top Indian manufacturers source components from nearby suppliers, cutting shipping and import fees. They reuse scrap, recycle packaging, and design products to need fewer parts. One plastic manufacturer in Gujarat reduced costs by 40% just by switching to a single mold that made three different product shapes. That’s ingenuity, not luck. And it’s why you’ll find Indian-made smartphones, medical devices, and solar inverters winning global contracts—because they’re built to be affordable, not just inexpensive.

When you look at the posts below, you’ll see real examples of how this works. From how to pitch your idea to a low-cost factory, to which chemicals give the highest profit margins, to how Tamil Nadu became India’s electronics export leader—all of it ties back to one truth: the cheapest manufacturing isn’t about being the cheapest. It’s about being the smartest.