Factory Challenges: Common Problems and Real Solutions in Indian Manufacturing

When you think of a factory, you might picture robots assembling phones or workers lining up on a production line. But behind the scenes, factory challenges, the hidden obstacles that disrupt production, planning, and profitability in industrial settings. Also known as manufacturing problems, these issues aren’t just theoretical—they’re daily realities for small and medium factories across India. From delayed raw materials to workers quitting mid-shift, these problems don’t show up in annual reports. They show up as missed deadlines, lost orders, and empty warehouses.

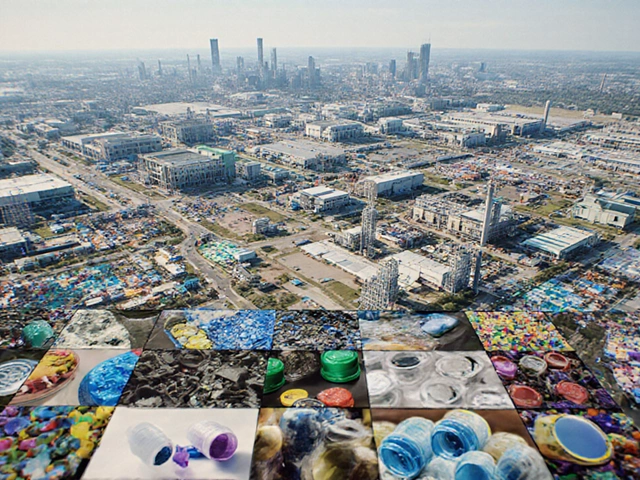

One of the biggest supply chain issues, breaks in the flow of materials, parts, or components needed to keep production running. Also known as logistics bottlenecks, they’ve hit Indian factories hard since 2020. A plastic manufacturer in Ludhiana told us he waited 47 days for a single type of resin last year. Meanwhile, labor shortage, the inability to hire or keep skilled workers needed to operate machines and manage production. Also known as workforce gaps, it’s worse in tier-2 cities where young workers leave for IT jobs in Bangalore or Hyderabad. Even when you find people, training them takes time you don’t have. And then there’s manufacturing efficiency, how well a factory turns inputs like materials and labor into finished products without waste. Also known as production performance, it’s the difference between making 100 units a day and 150—with the same staff and machines. Many factories still rely on paper checklists and guesswork. The ones that survive? They track everything: machine downtime, scrap rates, shift turnover. They use the 5 M’s—Manpower, Machines, Materials, Methods, Measurement—to find the leaks.

These aren’t abstract concepts. They’re the same problems covered in posts about government schemes helping factories cut energy costs, how small manufacturers in Tamil Nadu are beating supply chain delays by working directly with local suppliers, and why some food processing units are switching from batch to continuous production to reduce labor waste. You’ll find real stories from owners who fixed their biggest headaches—not with expensive tech, but with simple changes: better scheduling, cross-training workers, negotiating bulk material deals. This collection isn’t about theory. It’s about what’s broken, who’s fixing it, and how you can too.