Forming Processes in Manufacturing: What They Are and How They Shape Indian Industry

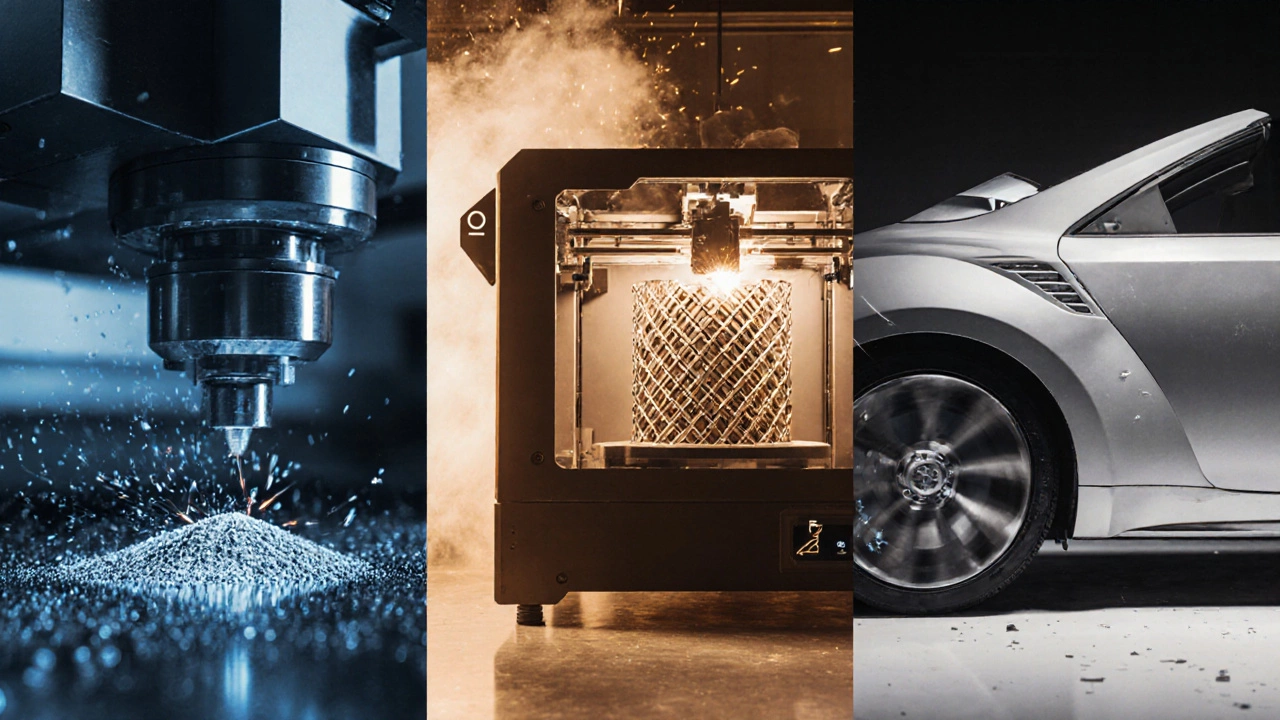

When you think about how a smartphone case, a car panel, or a medical device gets its shape, you’re thinking about forming processes, the methods used to reshape raw materials like metal, plastic, or sheet stock into finished parts without adding or removing material. Also known as shaping operations, these are the quiet backbone of every factory that turns raw stock into something useful. Unlike cutting or drilling, forming doesn’t waste material—it bends, stretches, presses, or molds it into the exact shape needed. This makes forming not just efficient, but critical for cost control and sustainability in today’s manufacturing world.

There are several key types of forming processes you’ll find in Indian factories. metal forming, includes techniques like stamping, bending, and deep drawing—common in making parts for electronics, appliances, and auto components. Then there’s plastic forming, where heated plastic is molded under pressure into housings, containers, or connectors. You’ll see these in every electronics assembly line across Tamil Nadu and Gujarat. Even small manufacturers use simple forming tools—like hand presses or bench brakes—to make custom brackets or enclosures. These aren’t just big factory tricks; they’re practical skills that let local makers compete.

Forming processes tie directly into the 5 M's of manufacturing—Machines, Materials, Methods, Manpower, and Measurement. Pick the wrong forming method, and you waste material, slow down production, or end up with defective parts. Get it right, and you cut costs, meet quality standards, and qualify for government incentives under Make in India. That’s why every small manufacturer, from a workshop in Ludhiana to a plant in Chennai, needs to understand which forming technique fits their product, volume, and budget.

What you’ll find in the posts below are real examples of how forming shows up in Indian manufacturing. From how plastic parts are molded for solar inverters to why stamping is the go-to for electronics housings, these articles show you the practical side—not theory, not fluff. You’ll see how small factories use forming to stay competitive, how government schemes support tooling upgrades, and why mastering these techniques can be the difference between surviving and thriving.