Honda Engine Production: How India Fits Into the Global Manufacturing Story

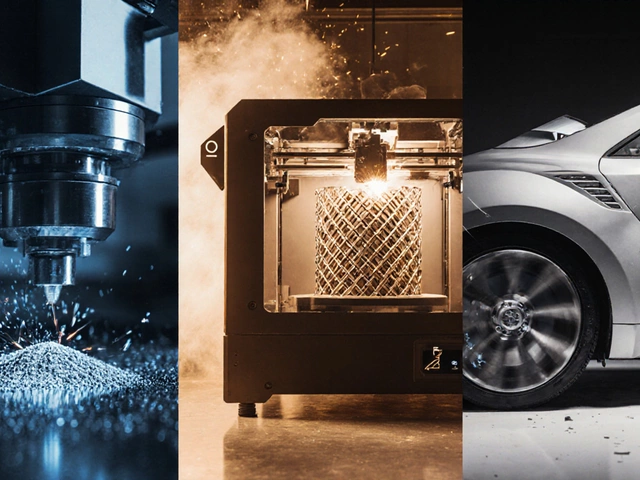

When you think of Honda engine production, the process of designing, assembling, and testing small internal combustion engines used in cars, motorcycles, and generators. Also known as Honda powertrain manufacturing, it’s a high-precision operation that blends Japanese engineering with global supply chains. India isn’t just a market for these engines—it’s a major production hub. Honda Motorcycle & Scooter India (HMSI) runs one of the largest engine plants in the country, making over 10 million engines a year. These aren’t just for local bikes. They’re shipped to over 30 countries, from Southeast Asia to Latin America.

This isn’t luck. It’s the result of a carefully built ecosystem. Indian auto component suppliers, local manufacturers that produce pistons, valves, crankshafts, and other engine parts for global brands like Honda. Also known as automotive Tier 1 and Tier 2 suppliers, they’ve evolved from simple assemblers to tech-driven partners. Companies like Bharat Forge and Sundaram Fasteners now supply precision parts to Honda’s Indian plants, meeting global quality standards. The government’s Production Linked Incentive (PLI) scheme pushed this further, giving manufacturers cash rewards for boosting local production. That’s why Honda expanded its India plant to make not just engines, but entire powertrains—gearboxes, clutches, and all.

What’s interesting is how this ties into bigger trends. Manufacturing in India, the growth of industrial production across electronics, autos, and machinery, driven by cost efficiency, skilled labor, and policy support. Also known as Make in India, it’s reshaping how global brands think about supply chains. After years of relying on China, companies like Honda are moving production to India not just to save money, but to reduce risk. The 2020-2022 supply chain disruptions proved that putting all your eggs in one basket is dangerous. India’s growing port capacity, skilled welders and machinists, and stable policy environment made it the next logical step.

You’ll find posts here that dig into how startups pitch to manufacturers like Honda, what it takes to qualify as a supplier, and how profit margins work in engine production. You’ll also see how Tamil Nadu became the engine-making capital of India, why small factories are now making parts for global giants, and what the 5 M’s of manufacturing really mean on the factory floor. This isn’t theory. It’s what’s happening in real plants, with real workers, making real engines that power millions of vehicles worldwide.