Idea Submission: How to Get Your Manufacturing Idea Heard and Funded

When you have a manufacturing idea, a tangible concept for a product that can be made in India with real demand. Also known as product innovation, it only becomes valuable when someone listens—and acts. Most ideas die because they’re never pitched right. Not because they’re bad. Because they’re buried in emails, vague messages, or unprepared presentations. The difference between an idea that goes nowhere and one that gets funded? How it’s submitted.

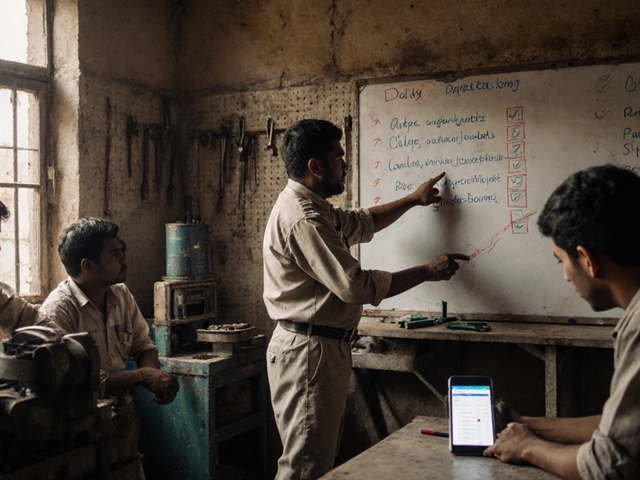

A strong idea submission, a structured, evidence-backed proposal presented to a manufacturer or investor. Also known as product pitch, it doesn’t need fancy slides. It needs proof: a working prototype, a cost breakdown, and evidence that people will buy it. Look at the posts here—people who got funding didn’t just say, "I made this." They showed unit economics, named their target customers, and explained why local production made sense. One maker in Tamil Nadu got seed funding because he brought 50 pre-orders from local clinics. Another in Gujarat won over a factory owner by showing exactly how much cheaper his part was to make than importing it. You don’t need to be a tech genius. You need to be clear, concise, and credible.

Manufacturers don’t want vague dreams. They want problems they can solve. Your idea submission should answer: What’s broken? Why can’t it be fixed now? Why me? Why here? Why now? The manufacturing partnership, a working relationship between an inventor and a production facility to bring a product to market. Also known as contract manufacturing, it’s not about giving away your idea—it’s about finding someone who can build it better, faster, and cheaper than you can alone. The best submissions come with a simple ask: "Can you make this? What would it cost? What do you need from me?" That’s it. No fluff. No jargon. Just facts and a clear next step.

What you’ll find below are real stories from people who got their ideas off paper and into production. From food processing units that scaled with local grants, to electronics makers who nailed their pitch using the 5 M’s of manufacturing, to startups who avoided equity loss by pre-selling before building. These aren’t theories. They’re tactics. And they all started with a single, well-prepared idea submission.