IKEA Expansion: How Global Retail Moves Are Reshaping Indian Manufacturing

When IKEA expansion, the global furniture retailer’s push into new markets like India, driven by demand for affordable, flat-pack design and local production. Also known as Swedish retail manufacturing strategy, it’s not just about selling furniture—it’s about reconfiguring entire supply chains, labor models, and factory systems to meet its scale and cost targets. This isn’t a one-off store opening. It’s a long-term bet on India’s manufacturing base, and it’s forcing local suppliers, small workshops, and even big players to rethink how they operate.

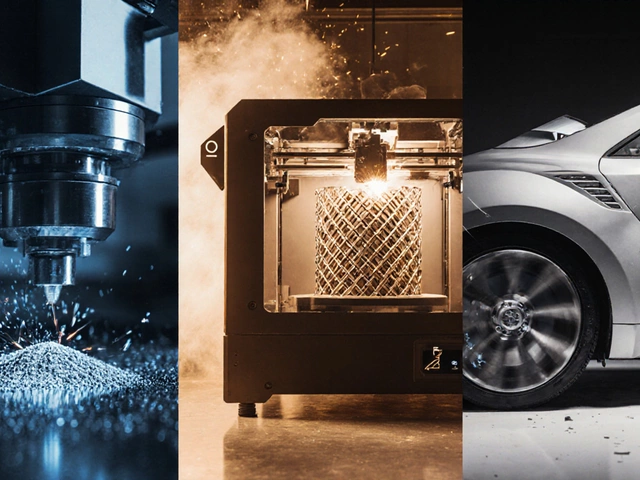

Behind every IKEA shelf is a network of Indian factories that now make drawers, legs, and panels to exact specs. This means furniture manufacturing, the process of turning raw wood, metal, and composite materials into finished home products, often at high volume and low cost in India has shifted from small-batch craftsmanship to precision-driven production lines. Factories that once made custom beds for local markets now run automated CNC cutters to produce thousands of identical bookshelves. The retail supply chain, the end-to-end flow of goods from raw material to final customer, often involving logistics, warehousing, and quality control has become tighter, faster, and more data-driven. Suppliers now track inventory in real time, ship in full container loads, and meet strict environmental and labor audits just to stay on IKEA’s vendor list.

And it’s not just about making things cheaper. Make in India, the government initiative to boost domestic manufacturing by attracting foreign investment and improving infrastructure is working hand-in-hand with IKEA’s goals. The company has invested over $2 billion in India, built local sourcing hubs, and partnered with hundreds of small and medium enterprises. That’s thousands of new jobs, upgraded factories, and better training for workers. But it’s also raising the bar. If you’re a small manufacturer who used to sell to local retailers, you now have to compete with factories that have ISO certifications, automated painting lines, and global logistics partners.

What you’ll find in the posts below are real stories from Indian manufacturers who’ve either adapted to this shift—or been left behind. You’ll see how a tiny workshop in Tamil Nadu started making IKEA-style hinges, how a textile mill in Gujarat pivoted to making fabric for upholstered chairs, and why some factories still struggle with consistency despite having the machines. This isn’t theory. It’s happening right now, in factories across the country, changing how India makes things—and who gets to make them.