Indian cars expensive: Why they cost more and what’s really behind the price

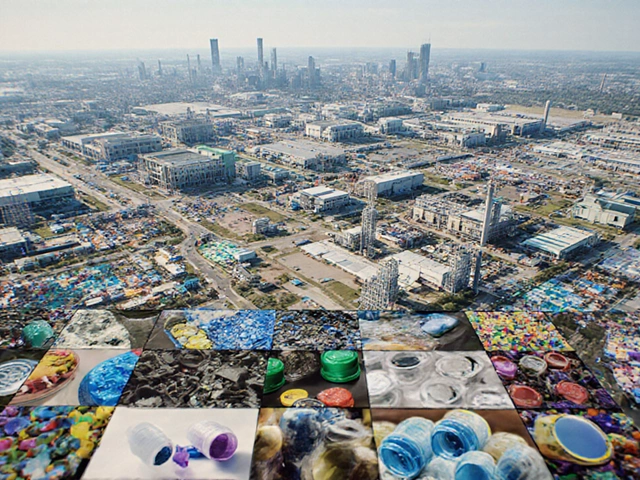

When you see the price tag on a new car in India, it’s easy to think it’s just taxes or luxury branding. But the real story starts with car manufacturing India, the complex system of local assembly, imported parts, and limited scale that drives up costs. Also known as domestic automotive production, this system isn’t built for mass efficiency like in China or Germany—it’s a patchwork of partnerships, import duties, and small-batch assembly lines that make every car more expensive before it even hits the showroom. Even the cheapest models carry a premium because most components—from engines to electronics—are imported or assembled under strict compliance rules that add layers of cost.

Look closer and you’ll see how automotive industry India, a sector still catching up in vertical integration and supply chain control. Also known as Indian auto manufacturing, it relies heavily on foreign tech for critical parts like ECUs, lithium batteries, and transmission systems. Unlike countries where automakers own their own steel mills or semiconductor plants, Indian manufacturers buy most of these from abroad, paying extra for shipping, tariffs, and currency swings. This isn’t just about making cars—it’s about making them with parts that weren’t made here. The result? A car that costs ₹8 lakh in India might cost ₹6 lakh in Thailand or Indonesia, even with similar features. And while brands like Tata and Mahindra are pushing hard to localize production, they’re still playing catch-up in areas like battery cells, sensors, and high-precision molds.

Then there’s the car pricing India, the hidden math behind what you pay at the dealership. Also known as retail automotive cost, it includes not just the factory price but GST, road tax, insurance, dealer margins, and logistics fees—all stacked on top of each other. In many cases, taxes make up over 40% of the final price. Meanwhile, countries like Vietnam or Mexico have flat tax structures for locally made cars, and China subsidizes EV components at scale. India doesn’t. And while the government pushes Make in India, the ecosystem hasn’t fully caught up. You can’t call a car "Made in India" if 70% of its value comes from imported parts.

What’s surprising is that the most affordable cars in India—like the Tata Tiago or Maruti Alto—are often the most profitable for manufacturers, not because they’re cheap to make, but because they sell in huge volumes. But even then, they’re priced higher than similar models elsewhere. The gap isn’t about quality—it’s about infrastructure. No Indian factory has the same level of automation as a Tesla Gigafactory or a Hyundai plant in Brazil. No Indian supplier produces the same volume of standardized wiring harnesses or dashboard modules. That inefficiency gets passed to you.

So when you ask why Indian cars are expensive, the answer isn’t simple. It’s not just one thing—it’s the combination of limited local production, high import dependency, fragmented supply chains, and tax structures that weren’t designed for volume. But things are changing. More electronics are being made in Tamil Nadu. More batteries are being tested in Karnataka. More local suppliers are entering the game. The cost won’t drop overnight, but the path is clearer than ever.

Below, you’ll find real breakdowns of what’s actually made in India, who’s leading the charge, and how small manufacturers are quietly changing the game—without the hype.