Indian Electronics: What’s Made in India and Who’s Leading the Charge

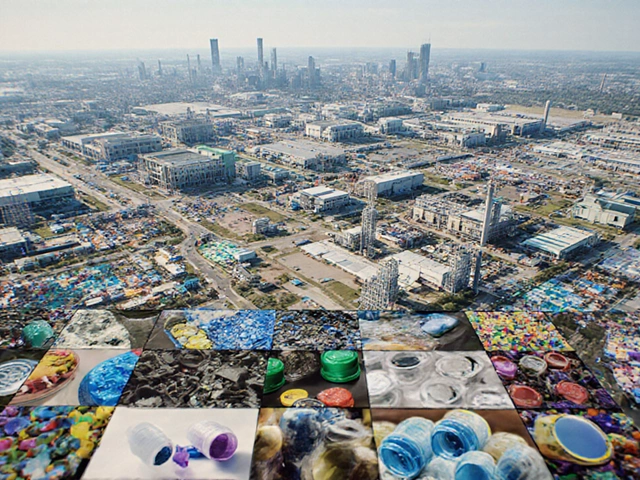

When we talk about Indian electronics, the growing ecosystem of devices designed, assembled, and exported from India. Also known as domestic electronics manufacturing, it’s no longer just about assembling phones—it’s about building the chips, circuits, and systems that power everything from medical devices to electric vehicles. India doesn’t just make gadgets anymore. It’s creating the backbone of a tech supply chain that’s catching up to, and in some cases, outpacing global players.

Take electronics manufacturing India, the full cycle of designing, sourcing, assembling, and testing electronic products within the country. It’s not a dream anymore. In 2024, India shipped over $12 billion in electronics exports—mostly from Tamil Nadu, where factories churn out smartphones, TVs, and solar inverters at scale. Companies like Samsung, Foxconn, and even local startups now operate massive production lines here. And it’s not just big names. Small manufacturers are stepping up too, making things like smart meters, LED drivers, and wearable health monitors in small workshops that are quietly becoming critical links in the chain.

The electronics supply chain India, the network of suppliers, logistics, testing labs, and component makers that support local production is finally coming together. Ten years ago, you’d need to import every resistor and capacitor. Now, you can get them from Gujarat, Pune, or Bengaluru. The government’s production-linked incentive (PLI) schemes pushed factories to invest locally. The result? More than 95% of smartphones sold in India are now made here. That’s not just a number—it’s a shift in power. It means more jobs, more innovation, and more control over pricing and quality.

But what’s actually being built? Smartphones? Sure. But also medical monitors used in rural clinics, inverters that keep homes powered during blackouts, and circuit boards for electric scooters made by Indian brands. These aren’t just exports—they’re solutions built for Indian needs, then scaled globally. And the people behind them? Not just engineers in Bangalore. They’re welders in Tirunelveli, quality testers in Noida, and factory owners in Ludhiana who learned to run automated lines on the job.

If you’re wondering whether India can compete in tech beyond software, the answer is right in your pocket. The phone you use? Chances are it was assembled here. The solar panel on your roof? Likely had its inverter made in a factory less than 500 km away. This isn’t about nationalism—it’s about economics, efficiency, and real industrial progress. Below, you’ll find real stories from inside these factories: who’s winning, what’s being made, how funding works, and why Tamil Nadu leads while other states are catching up fast.