Industrial Equipment: What It Is, How It Works, and What’s Made in India

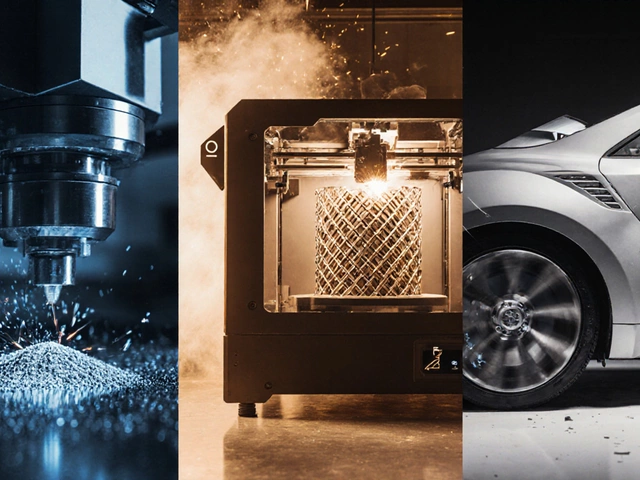

When you think of industrial equipment, machinery used to produce goods at scale in factories and plants. Also known as manufacturing machinery, it includes everything from conveyor belts and CNC routers to injection molders and automated welding arms. This isn’t just big, noisy machines in a warehouse—it’s the backbone of everything from your smartphone to the medicine in your cabinet. In India, industrial equipment is no longer just imported. Local factories are building, modifying, and scaling their own tools to meet demand, cut costs, and compete globally.

Production equipment, the specific tools used in a factory’s daily workflow. Also known as factory tools, it’s what turns raw materials into finished products. A small plastic parts maker in Ludhiana might use a $10,000 injection molding machine. A food processor in Tamil Nadu runs a continuous batch line that fills 5,000 pouches an hour. These aren’t theoretical setups—they’re real, running right now, often in places you’ve never heard of. And they’re getting smarter. Industrial automation is creeping into even small shops, thanks to affordable sensors, open-source controls, and government training programs that help makers upgrade without going broke.

What’s interesting is how industrial automation, using control systems and robotics to operate equipment with minimal human input. Also known as automated production, it’s transforming who can compete in manufacturing. You don’t need a billion-dollar plant anymore. A startup in Gujarat can now run a semi-automated electronics assembly line with just five people, thanks to modular equipment and plug-and-play controllers. The 5 M’s of manufacturing—Manpower, Machines, Materials, Methods, and Measurement—are still the foundation, but now they’re being redefined by digital tools and local innovation. Even food processing units, once seen as low-tech, now use automated sorting, vacuum sealing, and real-time quality sensors to meet export standards.

India’s manufacturing scene isn’t about replacing big players—it’s about making the right tools for the right jobs. Whether you’re running a small workshop or scaling up, understanding what industrial equipment actually does, how it’s used, and where it’s made locally gives you a real edge. Below, you’ll find real stories from Indian factories: how startups bought their first machine, what government schemes helped them upgrade, which equipment delivers the highest ROI, and how small players are beating global giants by being smarter, not bigger.