Manufacturing Efficiency: How to Cut Waste, Boost Output, and Keep Costs Low

When we talk about manufacturing efficiency, the ability to produce more goods with fewer resources, less time, and lower waste. Also known as production efficiency, it's what separates companies that survive from those that struggle—even in tough markets. It’s not about working harder. It’s about working smarter. A factory that runs smoothly doesn’t just save money—it wins contracts, keeps workers happy, and stays ahead of competitors who are still stuck in old ways.

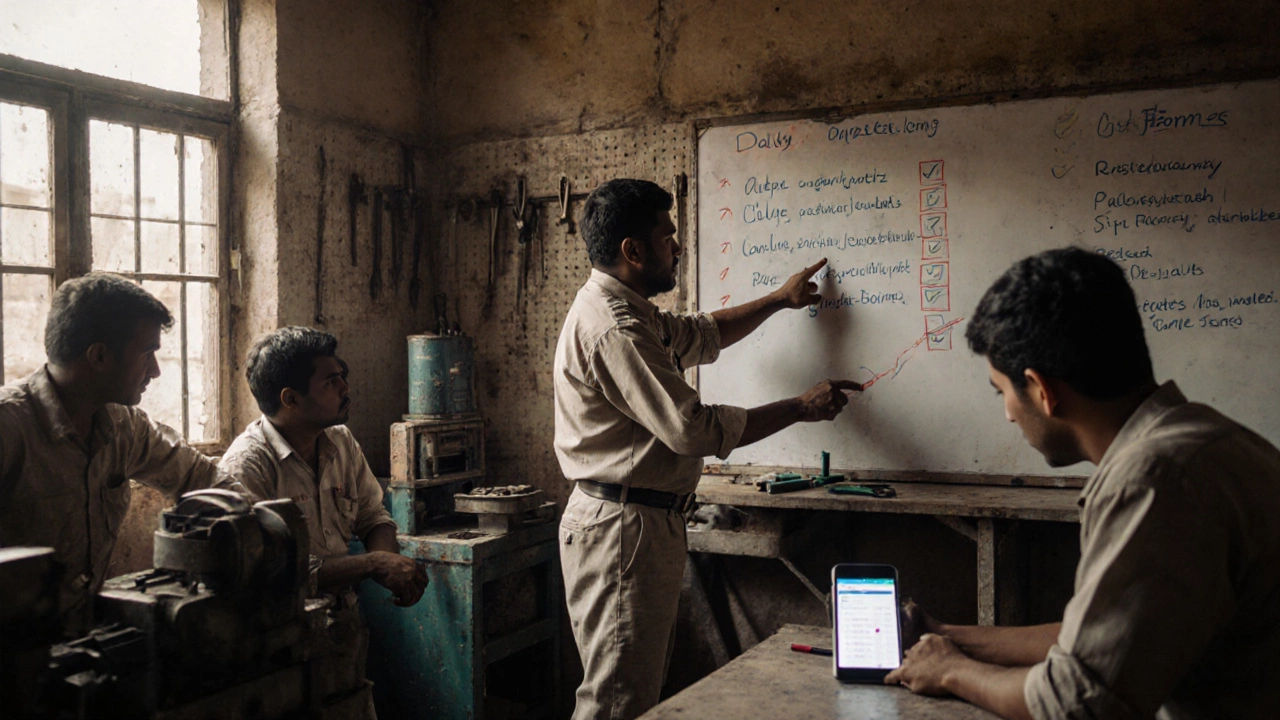

Real manufacturing efficiency shows up in small, daily choices: reducing machine downtime, cutting material waste, training workers to spot bottlenecks, and using data to predict breakdowns before they happen. It’s not magic. It’s method. Companies in Tamil Nadu and Gujarat are already doing it—using simple tools like 5S, lean principles, and real-time monitoring to squeeze out waste. You don’t need a billion-dollar budget. You need clarity. For example, one small electronics maker in Coimbatore cut its scrap rate by 40% in six months just by organizing its workspace and tracking where materials got lost. That’s efficiency. Not theory. Real results.

Efficiency isn’t just about machines. It’s about lean manufacturing, a system focused on eliminating waste in every step of production. It’s about operational efficiency, how well your entire system—from ordering parts to shipping finished goods—flows without friction. And it’s tied directly to manufacturing costs, the total money spent to turn raw materials into sellable products. If your costs are rising but output isn’t, something’s broken. The good news? Fixing it doesn’t require new tech. Often, it just means asking better questions: Why is this machine idle 3 hours a day? Why are we ordering 500 units when we only use 300? Who’s responsible for tracking this?

The posts below show you exactly how Indian manufacturers are doing this right. You’ll see how small shops cut costs without layoffs, how food processors streamline lines to meet demand, how electronics makers reduce scrap, and how even textile factories turned around after collapse by focusing on what really matters: doing the right thing, the right way, every time. No fluff. No jargon. Just what works.