Manufacturing Management: How to Run a Factory That Actually Works

When you hear manufacturing management, the system of planning, organizing, and controlling production to meet quality, cost, and delivery goals. It's not just about supervisors yelling at workers—it's the quiet backbone of every product you use, from your phone to your medicine. This is where decisions get made: what to make, when to make it, who does what, and how to fix it when things go wrong. And in India, where factories range from tiny workshops in Tamil Nadu to massive plants in Gujarat, good manufacturing management makes the difference between survival and growth.

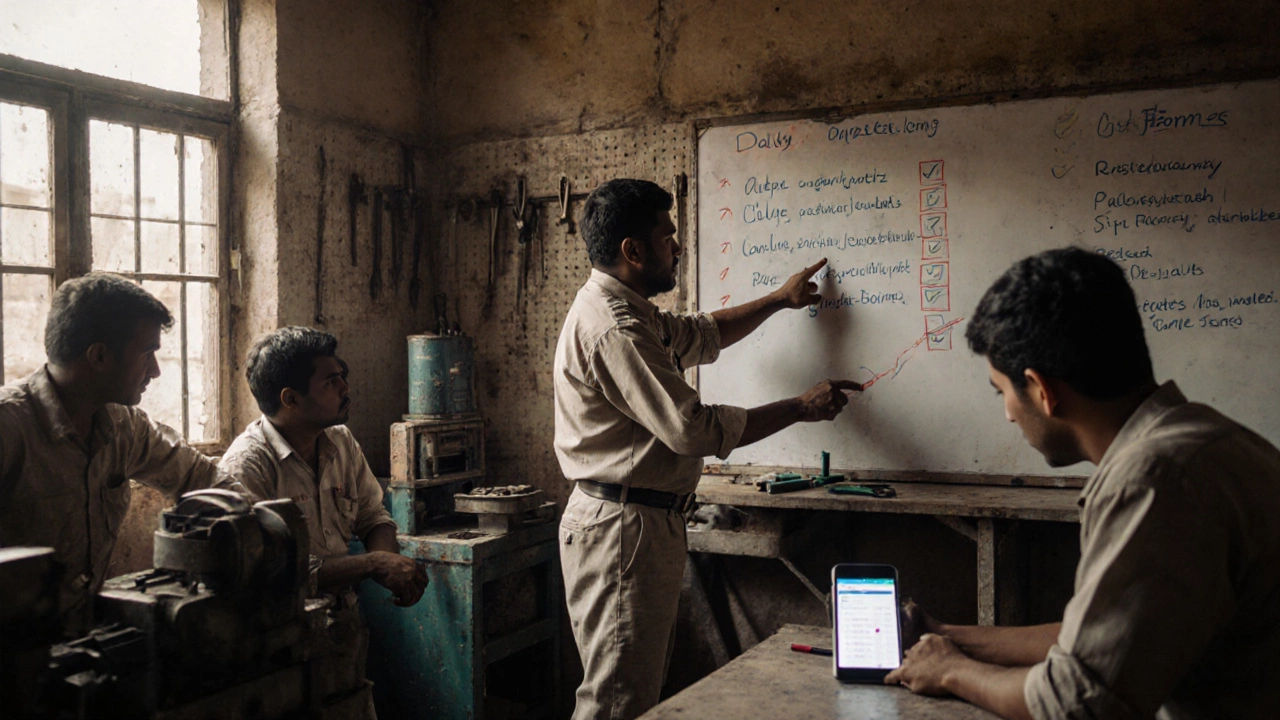

Production planning, the process of scheduling resources and materials to meet output targets is where most factories fail. You can have the best machines, but if you don’t know how many units to produce next week—or worse, if you’re making the wrong thing—you’re losing money before you turn the first screw. Factory operations, the day-to-day execution of production activities including labor, equipment use, and workflow is where theory meets reality. A single broken conveyor belt can shut down a line. A miscommunication between shifts can ruin a batch. And in small manufacturing units, one person often wears five hats—planner, technician, quality checker, and sometimes even the accountant.

Good manufacturing efficiency, the ability to produce more with less waste, time, or cost doesn’t come from buying fancy robots. It comes from fixing the little things: reducing setup time, training workers to spot defects early, tracking inventory in real time, and listening to the people on the floor. Look at the posts below—you’ll see how Cipla keeps its pharma lines running smoothly, how food processors in Maharashtra cut waste by switching from batch to continuous lines, and how startups in Bengaluru learned to pitch their ideas to manufacturers by understanding their pain points.

Manufacturing management isn’t about big budgets. It’s about smart choices. It’s knowing when to automate and when to keep it simple. When to hire and when to train. When to push for speed and when to slow down for quality. The posts here don’t talk about theory—they show you what works in real Indian factories. Whether you run a small workshop or dream of scaling up, what follows is the practical guide you won’t find in textbooks.