Manufacturing Methods: How Products Are Made in India Today

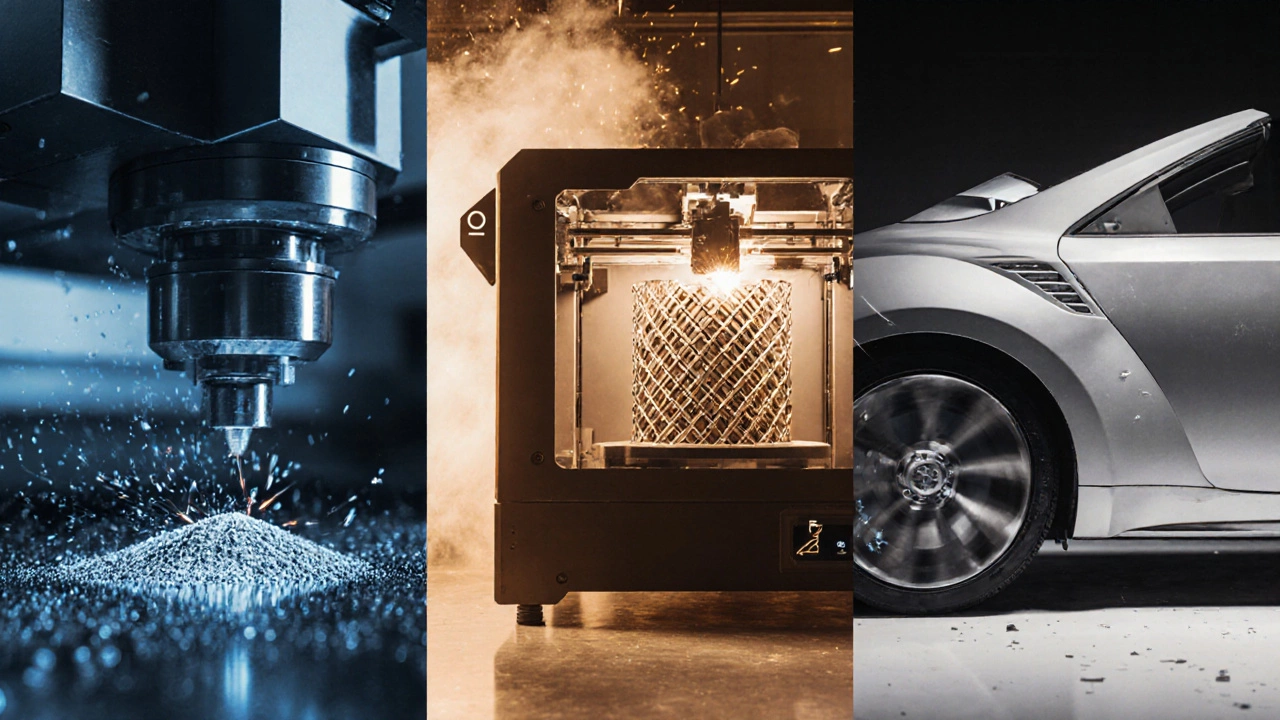

When we talk about manufacturing methods, the specific ways goods are produced, from raw material to finished product. Also known as production techniques, it's not just about machines—it's about how decisions on Manpower, Machines, Materials, Methods, and Measurement come together to make something real. In India, these methods vary wildly. A small manufacturer in Tamil Nadu might hand-assemble medical devices in a 500-square-foot workshop, while a plant in Gujarat uses automated lines to mass-produce solar inverters. Both are using manufacturing methods—but the goals, scale, and tools are completely different.

What you choose as a manufacturing method affects everything: your profit margin, your ability to scale, even your eligibility for government subsidies. The 5 M's aren’t just theory—they’re the checklist used by factories applying for Make in India incentives. If your method doesn’t include proper Measurement, you won’t qualify for training grants. If your Materials aren’t tracked, you can’t prove compliance. And if your Method is outdated, you’ll lose to competitors who switched to batch or continuous processing. Food processors, electronics assemblers, plastic molders—they all pick methods based on volume, cost, and customer demand. A startup making custom phone cases won’t need the same setup as a company churning out 10,000 units a day. The right method isn’t the most advanced one—it’s the one that fits your business size, your cash flow, and your market.

India’s manufacturing landscape isn’t one-size-fits-all. You’ll find artisan producers using simple tools to make high-margin food products, while big players like Reliance run fully integrated textile lines from fiber to retail. Some methods focus on speed and volume. Others prioritize quality and customization. The posts below show you exactly how these methods play out in real businesses—whether you’re pitching an idea to a factory, choosing a plastic supplier, or trying to boost your profit margin without raising prices. You’ll see which methods work for small shops, which ones get government support, and which ones are fading out. No fluff. Just what’s actually happening on the factory floor across India today.