Manufacturing Principles: Core Methods, Practices, and Real-World Applications

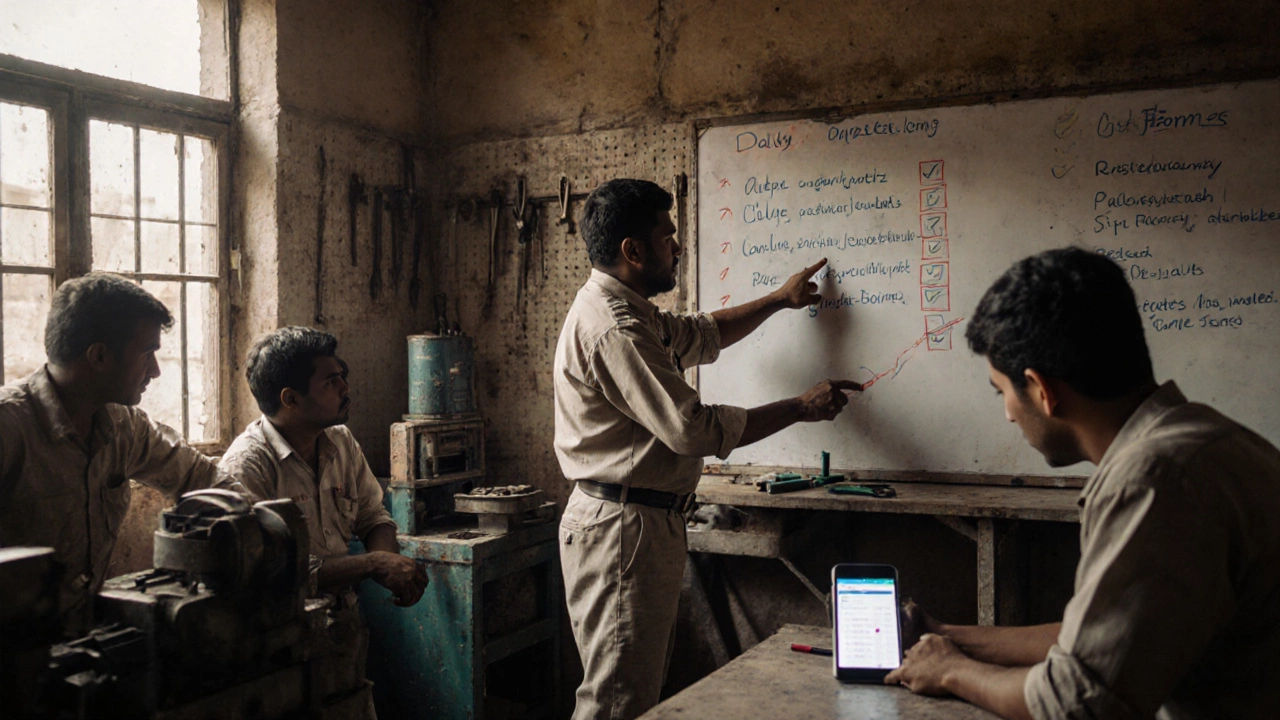

When you hear manufacturing principles, the foundational rules that guide how goods are made efficiently, reliably, and profitably. Also known as production fundamentals, these are the unchanging rules behind every product you use—from your phone to your morning coffee maker. They’re not fancy theories. They’re the daily decisions makers in Tamil Nadu factories, small workshops in Ludhiana, and electronics assembly lines in Bangalore make to keep things running without wasting time, material, or money.

These manufacturing principles show up in seven clear steps: design, sourcing, processing, assembly, testing, packaging, and logistics. But they also live in the 5 Ps of manufacturing, Production, Process, People, Plant, and Performance—the five pillars every successful shop relies on. You can’t fix a broken line without understanding your people. You can’t scale without a solid plant layout. And you can’t stay profitable if your process isn’t lean. These aren’t buzzwords. They’re the reason some factories double output in a year while others barely survive.

Then there’s the manufacturing methods, the actual ways you turn raw material into finished goods—like machining, forming, or additive manufacturing. Each has its place. Machining cuts metal for precision parts. Forming bends and shapes it for car bodies. Additive—3D printing—lets small makers build complex prototypes fast. Choosing the right one isn’t about tech trends. It’s about your product, your volume, and your budget. That’s why Indian startups are skipping expensive automation and starting with simple batch processing, then scaling smart.

And it all ties back to performance. Profit margins in manufacturing aren’t magic. They come from controlling costs, reducing waste, and keeping machines running. That’s why the best manufacturers track every step—not because they’re obsessed with data, but because one extra minute of downtime or one percent more scrap can kill their bottom line. Whether you’re running a tiny food processing unit or an electronics assembly line, these principles don’t change. What changes is how you apply them.

Below, you’ll find real stories from Indian manufacturers who cracked funding without selling equity, chose the right processing unit for their product, pitched their idea to a factory owner, and found the most profitable chemicals or plastics to make. No theory. No fluff. Just what works on the ground—in small shops, in big plants, and everywhere in between.