Manufacturing Process: How Things Are Made in India and Why It Matters

When you hear manufacturing process, the series of steps used to turn raw materials into finished goods. Also known as production process, it’s the backbone of everything from your smartphone to the medicine in your cabinet. It’s not just about machines—it’s about people, timing, cost, and control. In India, this process has changed fast. Ten years ago, most electronics were imported. Now, over 80% of smartphones sold here are made locally. That shift didn’t happen by accident. It happened because someone figured out how to make each step of the manufacturing process faster, cheaper, and more reliable.

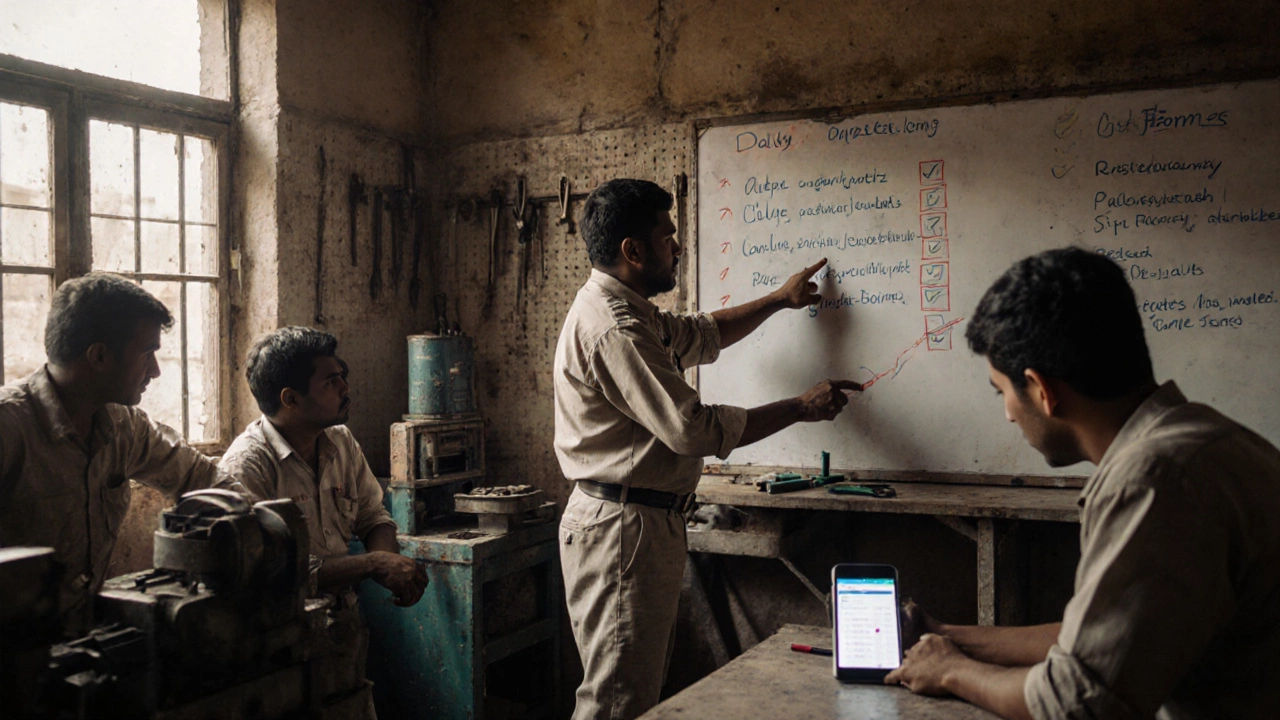

The manufacturing methods, the core techniques used to shape and assemble products. Also known as production techniques, it’s the toolkit behind every product. There are three big ones: machining (cutting metal), forming (bending sheet metal or plastic), and additive manufacturing (3D printing). Each has its place. A small maker might use 3D printing to test a prototype. A big factory uses stamping presses to make thousands of phone cases a day. Then there’s the manufacturing workflow, the sequence of tasks from design to delivery. Also known as production process, it’s the roadmap every factory follows. It starts with research, moves through sourcing, assembly, testing, and ends with shipping. Skip a step, and you get bad products. Get it right, and you build trust—and repeat customers.

What makes this all work in India? It’s not just cheap labor. It’s government schemes that help with power and training. It’s local suppliers stepping up to make parts instead of importing them. It’s startups pitching ideas directly to factories that know how to scale. You’ll find posts here that break down the seven essential steps of manufacturing, the core stages every production line must follow. You’ll see how food processors choose between batch and continuous lines. You’ll learn why Tamil Nadu leads in electronics exports—not because it’s lucky, but because its factories run the manufacturing process better than most. And you’ll see how small makers, with just a few machines and a lot of grit, are building profitable businesses without big investors.

This isn’t about theory. It’s about what’s actually happening in workshops, factories, and supply chains across India right now. Whether you’re trying to launch your own product, invest in a factory, or just understand how your phone got made, the posts below give you the real details—no fluff, no jargon, just clear answers.