Manufacturing Steps: How Products Are Made in India

When you think about manufacturing steps, the sequence of actions that turn raw materials into finished goods. Also known as production process, it's the backbone of every product you use—from your smartphone to the plastic container holding your morning yogurt. It’s not magic. It’s not guesswork. It’s a chain of clear, repeatable actions that any small factory in Tamil Nadu or a family-run workshop in Uttar Pradesh follows to make something real.

Every manufacturing process, the structured system used to produce goods starts with the same five pillars: Manpower, the people operating the machines and overseeing quality, Machines, the tools that cut, shape, or assemble materials, Materials, the raw inputs like plastic pellets, copper wire, or wheat flour, Methods, the step-by-step instructions that turn inputs into outputs, and Measurement, how you check if each step was done right. These are the 5 M’s—used by factories big and small across India to stay efficient, qualify for subsidies, and avoid costly mistakes.

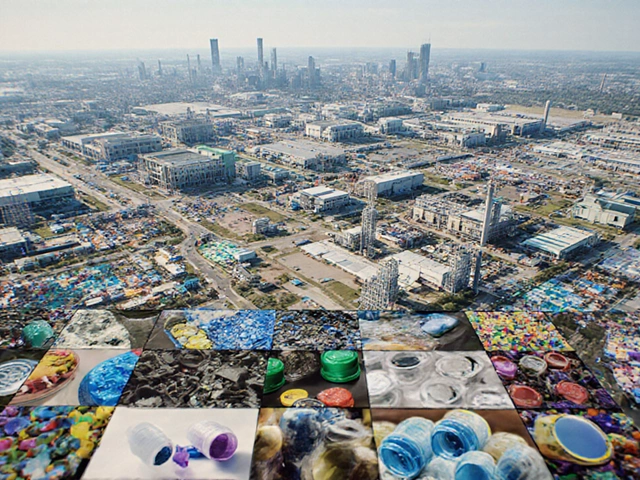

Some factories do everything by hand. Others use robotic arms and AI-driven quality checks. But the manufacturing steps stay the same. A smartphone gets assembled in stages: circuit boards are placed, screws are tightened, batteries are sealed, software is loaded, and each unit is tested. A food processor mixes ingredients, heats them, packages them, and labels them. A plastic bottle gets melted, molded, cooled, and inspected. The scale changes. The tools change. The logic doesn’t.

What makes Indian manufacturing unique isn’t the steps themselves—it’s how they’re adapted. Small manufacturers use low-cost tools to match global quality. Factories in Tamil Nadu export electronics because they nailed the measurement step. Food processors in Punjab cut waste by refining their methods. And startups who skip the basics? They fail fast. The ones who master the sequence—no matter how simple—build lasting businesses.

Below, you’ll find real examples from Indian factories showing exactly how these steps play out in food processing, electronics assembly, plastic molding, and more. No theory. No fluff. Just how things are actually made here—and how you can do it too.