Pay for Ideas: How to Turn Concepts into Profitable Manufacturing Projects

When people say pay for ideas, the act of compensating someone for a novel concept that can be turned into a tangible product or process. Also known as idea monetization, it’s not about scribbling on a napkin—it’s about proving your idea solves a real problem manufacturers are willing to pay to fix. Most ideas die because they’re too vague, too expensive to build, or don’t align with what’s actually being made in factories today. But some ideas? They get funded. Not because they’re genius, but because they’re executable.

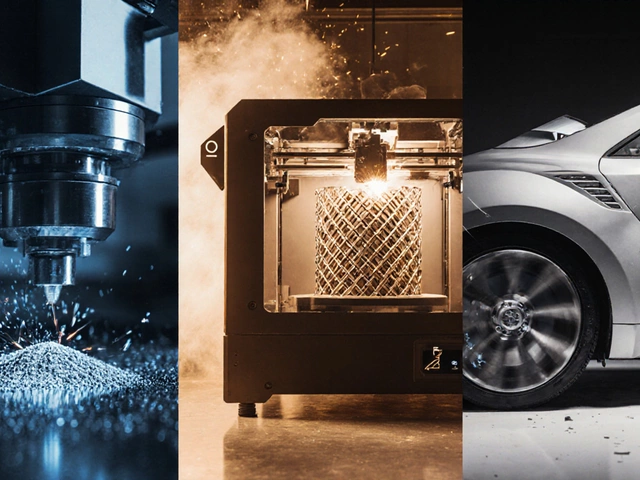

Manufacturers don’t buy dreams. They buy product development, the process of turning a concept into a manufacturable good with defined costs, materials, and volume potential. Think of it like this: if you have an idea for a new type of solar inverter, but you can’t tell a factory how much it costs to make, how many units they’d sell in a year, or what materials they’d need—you’re not selling an idea. You’re selling noise. But if you’ve tested it, built a prototype, and know your unit economics? That’s a conversation starter. Companies like Sydler Electro Manufacturing India see hundreds of ideas every year. Only a handful make it past the first meeting because they answer three questions: Can we build it? Will someone buy it? Can we make money on it?

That’s why the posts below aren’t about brainstorming. They’re about manufacturing partnerships, collaborations between inventors and factories where ideas are turned into products through shared risk, clear terms, and measurable outcomes. You’ll find real examples of how small makers in India got paid for their concepts—by pre-selling to customers, using government grants to de-risk production, or pitching directly to factories with cost breakdowns and sample units. You’ll see what kinds of ideas get traction in electronics, food processing, and plastics manufacturing—and which ones get ignored. You’ll learn how to structure your pitch so it doesn’t sound like a fantasy. And you’ll understand why the best ideas aren’t the loudest—they’re the ones that come with a price tag, a plan, and proof it can be made.

These aren’t theoretical guides. They’re field reports from people who’ve walked into factories with an idea—and walked out with a contract. Whether you’re a hobbyist with a prototype, a student with a patent, or a small business owner with a better way to make something, this collection shows you exactly how to turn your idea into something someone will pay for.