Production Planning: What It Is and How It Powers Indian Manufacturing

When you hear production planning, the organized process of scheduling resources, materials, and labor to meet manufacturing goals. Also known as manufacturing scheduling, it’s not just a spreadsheet—it’s the rhythm that keeps factories running without chaos. Without it, even the best machines sit idle, workers wait for parts, and orders pile up unfulfilled. In India, where small manufacturers make up over 95% of the industrial base, smart production planning isn’t optional. It’s what separates businesses that survive from those that just barely stay open.

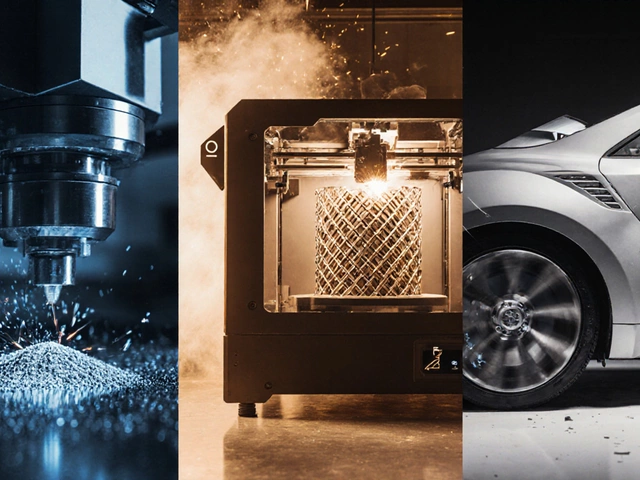

Production planning doesn’t work in a vacuum. It ties directly to the 5 M's of manufacturing, Manpower, Machines, Materials, Methods, and Measurement—the core pillars every small factory must master to qualify for subsidies and scale efficiently. You can’t plan production if you don’t know how many workers you have, what tools are broken, or how long a batch really takes. That’s why posts here break down real cases—from a plastic molding shop in Ludhiana tracking cycle times to a food processing unit in Tamil Nadu switching from batch to continuous flow to cut waste. It’s also why manufacturing methods, like machining, additive manufacturing, and forming, directly shape how you plan production. You don’t plan a 3D-printed part the same way you plan stamped metal parts. And if you’re trying to pitch your idea to a manufacturer, they’ll ask you one thing first: Do you have a production plan?

Production planning also links to the bigger picture: government schemes, supply chain delays, and labor shortages. In 2025, factories that didn’t plan ahead are still scrambling for components. Those that did? They’re filling orders while others wait. This collection shows you how real Indian manufacturers—from tiny workshops to mid-sized electronics assemblers—use simple, low-tech tools to build robust production schedules. You’ll see how a startup in Karnataka used pre-sales to lock in material orders before production even started. How a textile unit in Gujarat cut downtime by 40% just by measuring machine uptime. How a food processor in Maharashtra chose the right type of processing unit based on volume, not trends.

There’s no magic formula. But there are patterns. And this page gathers them all—no fluff, no theory without practice. What you’ll find below are real stories from Indian factories where production planning made the difference between profit and loss, growth and stagnation. Whether you run a small shop, are thinking of starting one, or just want to understand how things actually get made here, this is your guide to getting it right.