Profitable Factory Ideas: Real Manufacturing Businesses That Work in India

When you hear profitable factory ideas, businesses that turn raw materials into sellable goods with strong returns, most people think of big factories with robots and assembly lines. But the real money isn’t always in scale—it’s in focus. In India, the most successful small manufacturers don’t chase global volumes. They solve local problems with simple, reliable production. Think food processing units that turn surplus crops into shelf-stable snacks, or electronics assembly lines that build solar inverters for rural homes. These aren’t ideas from a textbook. They’re businesses running right now, making money, and hiring workers in Tamil Nadu, Gujarat, and Uttar Pradesh.

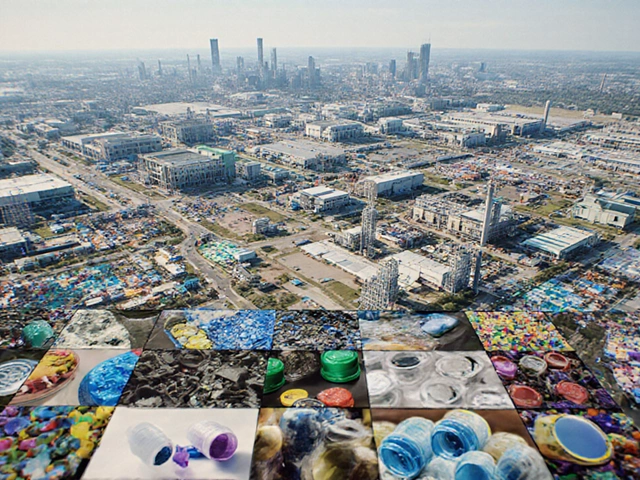

What makes a factory idea truly profitable? It needs three things: steady demand, low dependency on imports, and room to scale without massive capital. food processing units, facilities that preserve, package, or transform raw agricultural products are one of the most reliable categories. People always eat. And in India, where 60% of crops are lost due to poor storage, turning that waste into pickles, powders, or ready-to-eat meals isn’t just smart—it’s essential. Then there’s electronics manufacturing, the assembly and production of consumer and industrial electronic components. India now makes smartphones, medical devices, and EV parts locally. The government pushes this through incentives, and local demand keeps growing. You don’t need to build a chip. You can start by assembling circuit boards for water purifiers or solar charge controllers—products that every small town needs.

Profit margins in manufacturing aren’t magic. They come from control. Control over materials, control over labor, and control over distribution. A small manufacturer in Madurai who buys raw plastic locally, molds it into kitchen storage containers, and sells them door-to-door in nearby villages makes more per unit than a company that exports to Europe. Why? Fewer middlemen. Lower overhead. Faster feedback. The 5 M's of manufacturing, Manpower, Machines, Materials, Methods, and Measurement—the core pillars of efficient production aren’t just theory. They’re daily checklists for owners who survive. And when you combine that with a product people can’t live without—like medical supplies, food, or basic electronics—you get something that lasts through recessions, policy changes, and global supply shocks.

What you’ll find below aren’t vague suggestions like "start a bakery" or "make candles." These are real, documented manufacturing businesses running in India right now. From the pharmacist who started a capsule-filling unit to the engineer who built a small plant for solar inverters—each post shows the exact steps, costs, and margins. No fluff. No hype. Just what works when you’re starting small, working hard, and building something that lasts.