Small Business Manufacturing in India: How Local Makers Thrive

When you think of small business, a locally owned operation that produces goods with limited staff and capital, often focusing on quality over volume. Also known as small scale manufacturing, it doesn’t mean low impact. In India, small manufacturers are building everything from medical devices to solar inverters—often with just a handful of workers and a lot of grit. These aren’t just side hustles. They’re the backbone of India’s manufacturing revival, filling gaps big factories ignore and serving communities that global brands overlook.

What makes a small manufacturer, a business that produces goods in small batches, usually with hands-on processes and direct customer ties different from a big factory? They don’t chase mass production. They chase reliability. They fix problems fast. They adapt to local needs. A small manufacturer in Tamil Nadu might make custom circuit boards for rural clinics. One in Gujarat could be hand-assembling LED drivers for solar lights. These aren’t just products—they’re solutions built with local knowledge. And they’re not starting from scratch. Many use government schemes for training, subsidies, or low-cost equipment. The 5 M's of manufacturing, Manpower, Machines, Materials, Methods, and Measurement—the core pillars for running any efficient production unit aren’t just theory here. They’re daily checklists.

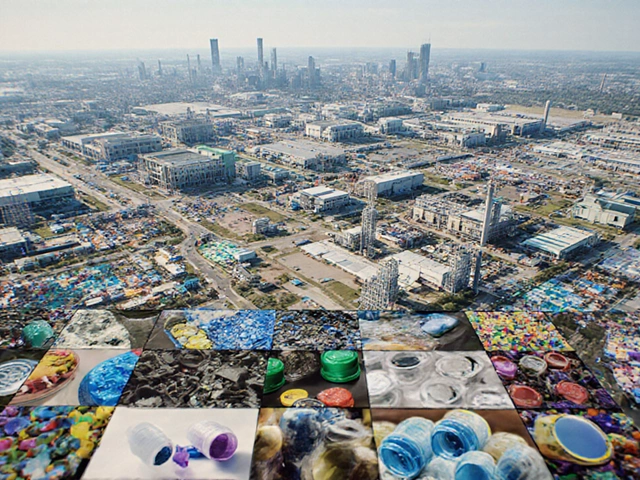

Profit margins in small manufacturing aren’t glamorous, but they’re real. One food processor in Madhya Pradesh made 32% gross margin by skipping branded packaging and selling straight to local shops. A plastic parts maker in Rajasthan cut material costs by 40% by partnering with nearby scrap recyclers. These aren’t outliers. They’re smart operators using the same tools big players do—just smarter. You don’t need a $10 million plant to compete. You need clear unit economics, a loyal customer base, and the willingness to start small and scale slowly.

And funding? It’s not just about venture capital. Many small manufacturers get their first money by pre-selling products, using local grants, or getting paid upfront by community buyers. One startup in Pune raised ₹5 lakh by selling 200 units of a custom medical device before they even built the first prototype. That’s the power of proving demand before you invest.

What you’ll find below are real stories from Indian small manufacturers—how they started, what broke, what worked, and how they’re still standing. No fluff. No theory. Just the facts from the factory floor.