Steel Production Comparison: How India Stacks Up Against Global Leaders

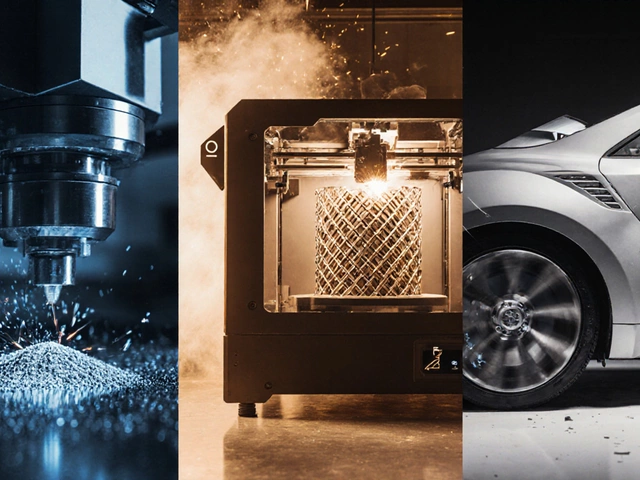

When you hear steel production, the process of turning iron ore and scrap metal into usable steel for buildings, cars, and machinery, you might think of massive furnaces and smokestacks. But today, it’s also about efficiency, government policy, and global supply chains. India, a rising force in global manufacturing with over 120 million tons of steel produced annually is now the second-largest producer in the world, behind only China. Meanwhile, the United States, home to the massive Gary Works steel mill and a long history of heavy industry still leads in high-grade specialty steel, even as its total output falls behind. And then there’s Japan, where precision and automation keep its steel industry lean and competitive despite smaller scale.

What makes one country’s steel production better than another’s? It’s not just volume. It’s energy use per ton, carbon emissions, access to raw materials, and whether the government supports modernization. India’s growth comes from domestic demand—infrastructure projects, EVs, and housing—plus policies like Make in India pushing local production. China dominates because it controls nearly every step: from mining iron ore to building the mills. The US relies more on recycling scrap steel, which is cheaper but limits output. And countries like Germany and South Korea focus on high-value steel for automotive and aerospace, where margins are higher than bulk construction steel.

When you look at the data, India isn’t just catching up—it’s redefining what’s possible with local resources and smart policy. But gaps remain: energy costs are higher than in China, technology adoption is uneven across mills, and export infrastructure still lags behind ports in Singapore or Rotterdam. That’s why the posts below dive into real comparisons: how much steel India actually makes versus the US, which Indian states produce the most, why some mills are upgrading while others shut down, and what it takes to compete on cost and quality. You’ll find breakdowns of production numbers, insights into government incentives, and even how small manufacturers are using recycled steel to stay alive. This isn’t theory. It’s what’s happening on the ground, in real factories, right now.