U.S. Steel Industry: Key Players, Plants, and What It Means for Global Manufacturing

When we talk about the U.S. steel industry, the backbone of American industrial output, responsible for building infrastructure, vehicles, and machinery since the 19th century. Also known as American steel manufacturing, it’s not just about rust and smokestacks—it’s a high-stakes game of scale, technology, and global competition. The industry still runs on massive facilities like Gary Works, the largest steel mill in the United States, located in Indiana, with the capacity to produce over 7 million tons of steel annually. Owned by U.S. Steel, Gary Works isn’t just a plant—it’s a symbol of how American manufacturing survives by reinventing itself, not just clinging to the past.

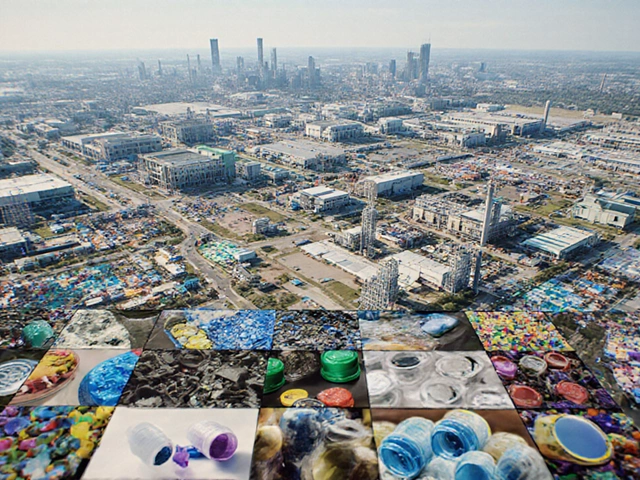

The U.S. Steel production, a term that covers everything from blast furnaces to electric arc furnaces using recycled scrap, has shifted dramatically. Decades ago, it was all about raw ore and coal. Today, it’s about efficiency, automation, and environmental pressure. Plants like Gary Works have spent billions upgrading to cleaner processes, reducing emissions while keeping output high. Meanwhile, competitors in Asia and Europe are pushing hard, making every ton of U.S.-made steel a fight for market share. The largest US steel plant, a title held by Gary Works for decades, represents the last of the giants that still dominate domestic supply. But even giants are feeling the squeeze from cheaper imports, supply chain delays, and labor shortages.

What does this mean for manufacturers elsewhere? If you’re sourcing steel for electronics enclosures, medical devices, or industrial machinery, the cost and reliability of U.S. steel directly affect your margins. Companies in India and Southeast Asia watch U.S. production closely—when Gary Works ramps up, prices shift. When it slows down, global buyers scramble. The U.S. steel industry isn’t just an American story. It’s a ripple effect across global supply chains.

Behind every steel beam in a factory, every motor in an EV, every solar panel frame—there’s a story from a mill like Gary Works. The U.S. steel industry doesn’t make headlines like tech startups, but it’s the silent engine behind so much of what’s made, sold, and used around the world. Below, you’ll find real breakdowns of how these mills operate, who owns them, and what’s next for the industry that built America—and still keeps it running.