Honda Engine Plant: What It Means for India’s Manufacturing Growth

When you think of a Honda engine plant, a large-scale facility that designs and builds internal combustion engines for motorcycles, cars, and generators. Also known as Honda Power Products manufacturing unit, it’s not just a factory—it’s a signal that India is becoming a serious hub for high-quality, export-ready engine production. This isn’t just about assembling parts. It’s about building precision components that meet global standards, right here in Uttar Pradesh or Tamil Nadu, with local workers trained to exacting specs. The Honda engine plant in India doesn’t just supply the domestic market—it ships engines to over 30 countries, making it one of the most efficient and scalable operations in Asia.

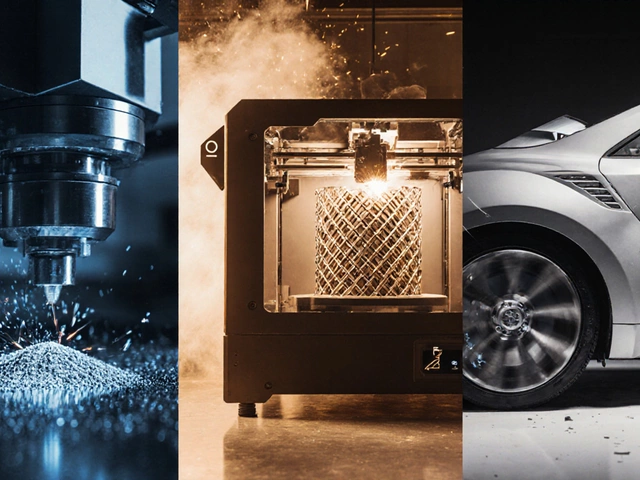

What makes this plant stand out? It’s the way it connects to other parts of India’s manufacturing ecosystem. The automotive manufacturing, the process of designing, engineering, and producing vehicles and their core components like engines, transmissions, and chassis sector here relies on a network of small suppliers who make everything from gaskets to exhaust manifolds. The Honda plant doesn’t just buy from them—it helps them upgrade their machines, adopt better quality control, and get certified for international exports. That’s how a single large plant lifts up dozens of small manufacturers. And it’s not unique to Honda. Similar ripple effects are happening with Maruti, Tata, and even global players like Bosch and Denso setting up shop in India.

India’s manufacturing in India, the growing sector that produces electronics, machinery, pharmaceuticals, and now high-precision engines using local labor, infrastructure, and government incentives is no longer about cheap labor. It’s about skill, consistency, and scale. The Honda engine plant proves that Indian factories can match Japanese engineering standards. And that’s why investors and startups are paying attention. If a company like Honda can build engines here that pass global emissions and durability tests, what’s stopping a local startup from making medical devices, solar inverters, or EV components?

You’ll find posts here that dig into how small manufacturers win contracts with giants like Honda, what it takes to qualify as a Tier-2 supplier, and how government schemes like Production Linked Incentive (PLI) are helping factories upgrade their lines. You’ll also see real numbers on profit margins in engine production, how Tamil Nadu leads in auto component exports, and why the 5 M’s of manufacturing matter more than ever in a plant that runs 24/7. This isn’t theory. It’s what’s happening on the factory floor—and if you’re building something in India, you need to understand how the big players are changing the rules.