Indian electronics production: How it works, who leads, and what’s next

When we talk about Indian electronics production, the growing ecosystem of companies designing, assembling, and exporting electronic goods within India. Also known as domestic electronics manufacturing, it’s no longer just about assembling phones—it’s about building chips, circuit boards, and smart devices from the ground up. This shift didn’t happen overnight. It’s the result of policy pushes like Make in India, a national initiative to boost local manufacturing and reduce import dependence, combined with global supply chain disruptions that made relying on China too risky. Now, factories from Tamil Nadu to Uttar Pradesh are turning out everything from smartphones to solar inverters, and the numbers show it: Tamil Nadu alone shipped over $12 billion in electronics in 2024.

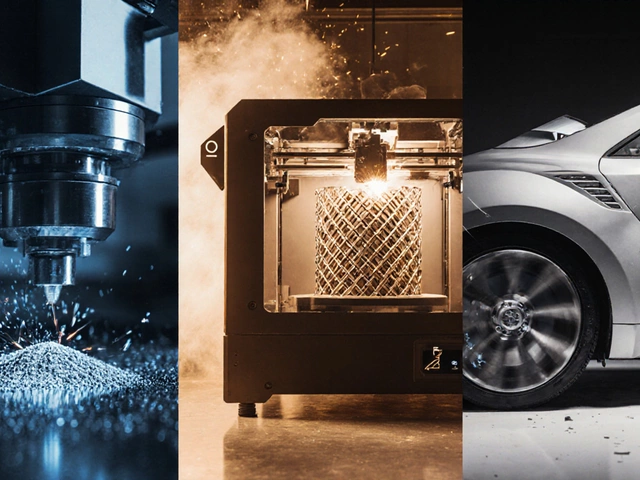

What makes Indian electronics production, the growing ecosystem of companies designing, assembling, and exporting electronic goods within India different today? It’s not just scale—it’s structure. You’ve got global giants like Samsung and Foxconn setting up massive plants, but also local startups building niche products: medical devices, smart meters, IoT sensors. These smaller players rely on the same five core pillars—Manpower, the skilled and semi-skilled workers who operate machines and test products, Machines, automated lines, SMT assembly tools, and testing rigs, Materials, local sourcing of PCBs, connectors, and raw plastics, Methods, lean production, batch sizing, and quality control systems, and Measurement, tracking defect rates, cycle times, and yield percentages. These are the same 5 M's of manufacturing that help small factories qualify for government grants and training programs.

And it’s not just about making things. It’s about selling them. Electronics export India, the shipment of Indian-made electronic goods to international markets is climbing fast, with top exporters like Reliance and Lava pushing into Africa, Southeast Asia, and Latin America. Investors are watching closely—not just for volume, but for margins. Profit in this space isn’t about selling cheap phones. It’s about high-margin components: battery packs, power adapters, smart home controllers. The businesses that survive aren’t the ones copying China—they’re the ones solving local problems with local tech.

What you’ll find below isn’t just a list of articles. It’s a map. A map of who’s winning, where the money’s going, what tools matter, and how a startup with one prototype can turn into a factory with a shipping container full of exports. Whether you’re a founder, a supplier, or just curious how your phone got made in India, this collection gives you the real stories—not the press releases.