Manufacturing Types: What They Are and How They Work in India

When we talk about manufacturing types, the different ways goods are produced at scale, from hand-made batches to fully automated lines. Also known as production methods, they determine how fast, cheap, and flexible your product can be made. In India, you won’t find just one kind of factory. You’ll find small workshops making custom parts, mid-sized plants assembling smartphones, and huge facilities churning out textiles or chemicals every hour. The type of manufacturing you choose shapes everything—your costs, your quality, even your ability to scale.

There are five main manufacturing types, the core models used across industries to turn raw materials into finished products: batch manufacturing, where products are made in groups—like food processing units making 500 jars at a time; continuous manufacturing, which runs 24/7 without stopping—think chemical plants or steel mills; mass production, used for high-volume items like smartphones or TVs, where every unit is identical; small scale manufacturing, where makers produce in low volumes with local tools and direct customer ties; and hybrid manufacturing, a mix of manual and automated steps, common in India’s growing electronics and medical device sectors. Each has trade-offs. Batch gives you flexibility but slower output. Continuous is efficient but needs big upfront investment. Small scale is low-risk but hard to grow fast.

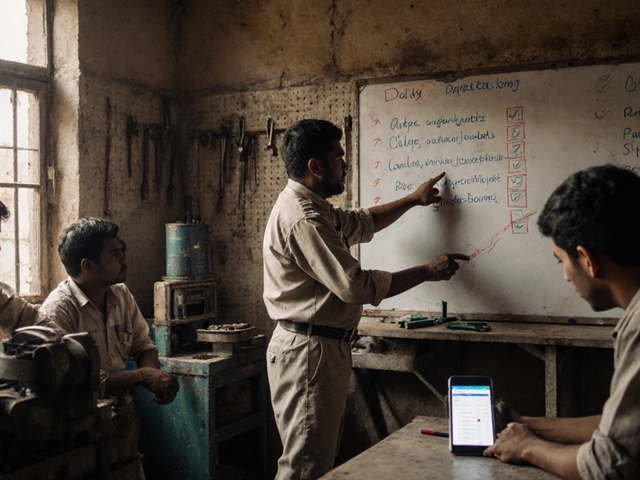

What’s clear from India’s manufacturing scene is that no single type wins. Tamil Nadu’s electronics exports rely on mass production. Reliance’s textile empire uses continuous lines. Meanwhile, local makers in Jaipur or Coimbatore thrive with batch and small scale methods, selling directly to niche buyers. The 5 M's of manufacturing, Manpower, Machines, Materials, Methods, and Measurement—key tools for improving any production setup help even the smallest shops optimize. Government schemes now push small manufacturers toward hybrid models, blending automation with human skill to compete globally. Whether you’re launching a startup or expanding a family business, picking the right manufacturing type isn’t about following trends—it’s about matching your product, market, and money.

Below, you’ll find real examples of how these manufacturing types play out across industries—from food processing units in Gujarat to electronics assembly lines in Chennai. You’ll see who’s winning with batch, who’s betting on continuous, and how small makers are using hybrid models to survive and grow. No theory. Just what’s actually happening on the factory floor in India today.