MOM in Manufacturing: What It Means and How It Powers Indian Factories

When you hear MOM, Manufacturing Operations Management. It's not just a buzzword—it's the backbone of how factories track, control, and improve what they make every day. Think of it as the nervous system of a production line: it tells you when a machine is down, who’s working on what, how much material is left, and whether the final product meets quality standards. In India’s growing manufacturing scene, where small factories are stepping up to compete globally, MOM isn’t optional—it’s the difference between barely surviving and scaling smartly.

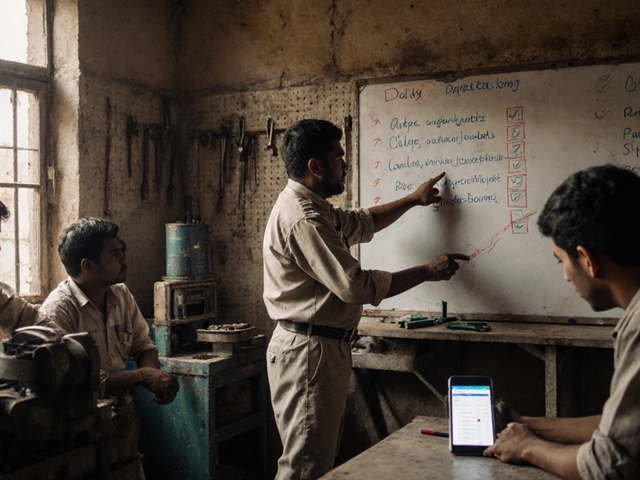

It’s not about fancy software alone. Manufacturing operations management includes the people, the processes, and the paper trails that keep things real. You don’t need a $100,000 system to start. Many small manufacturers in Tamil Nadu and Gujarat use simple spreadsheets, checklists, and daily huddles to do the same job. The goal? Reduce waste, cut delays, and avoid costly mistakes. And guess what? The Indian government’s production-linked incentive (PLI) schemes now reward factories that use structured systems like MOM to prove they’re efficient and scalable. That means if you’re tracking your output, machine uptime, or scrap rates—even manually—you’re already on the path to qualifying for support.

Related concepts like the 5 M's of manufacturing—Manpower, Machines, Materials, Methods, and Measurement—are the building blocks of MOM. If you know how much labor you’re using per unit, or which machine breaks down most often, you’re doing MOM. Same with manufacturing process optimization. Whether you’re making medical devices in Bangalore or plastic parts in Ludhiana, if you’re asking, "Why did this batch fail?" or "Can we do this faster?"—you’re engaging with MOM. It’s not magic. It’s just paying attention to what’s actually happening on the floor.

What you’ll find below are real stories from Indian manufacturers who used MOM to survive, grow, or win government grants. Some started with pen and paper. Others upgraded to digital tools. All of them learned that control isn’t about surveillance—it’s about clarity. You don’t need to be a tech giant to benefit. You just need to know what’s going on, why it matters, and how to fix it when it breaks.