New Technology in Manufacturing: What’s Really Changing the Game in India

When we talk about new technology, practical tools and systems that improve how goods are made, often using automation, data, or smarter processes. Also known as manufacturing innovation, it’s not just about robots waving arms in a sci-fi movie—it’s about small factories in Tamil Nadu using low-cost sensors to cut waste, or a startup in Pune building custom circuit boards faster than ever before. This isn’t theoretical. It’s happening right now in workshops, warehouses, and labs across India, driven by people who don’t wait for big budgets—they just solve problems with what’s available.

Electronics manufacturing, the process of building devices like smartphones, medical gear, and solar inverters locally. Also known as domestic electronics production, it’s one of the biggest areas where new technology is making a real difference. India doesn’t just assemble phones anymore—it designs the chips inside them, tests them on-site, and ships them out globally. Tamil Nadu alone exported over $12 billion in electronics last year, not because of luck, but because factories started using real-time quality tracking, AI-powered defect detection, and automated supply chain alerts. Meanwhile, small manufacturers are using open-source hardware and 3D printing to prototype in days, not months. You don’t need a billion-dollar plant to use these tools—you just need to know how to ask the right questions.

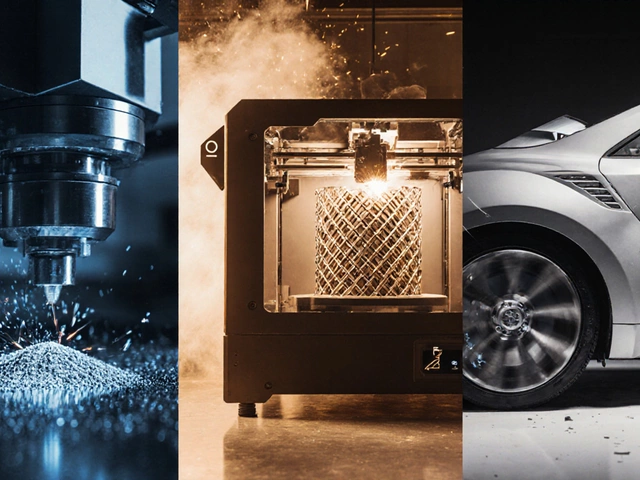

Manufacturing technology, the combination of machines, software, and methods used to produce goods efficiently. Also known as industrial tech, it’s what lets a single worker monitor ten machines at once, or a food processor reduce spoilage by 40% using smart temperature controls. This isn’t about replacing people—it’s about making them more powerful. The 5 M’s of manufacturing—Manpower, Machines, Materials, Methods, Measurement—are now being upgraded with digital twins, predictive maintenance, and cloud-based analytics. Even small factories are qualifying for government training programs because they’re adopting these tools, not because they’re huge. And it’s not just hardware. New technology includes better ways to pitch ideas to manufacturers, track profit margins in real time, and find the right suppliers without middlemen.

What you’ll find below isn’t a list of buzzwords. It’s a collection of real stories—how a startup got its first funding by proving demand with pre-sales, how Cipla kept control by sticking to affordable medicine despite global pressure, how a plastic maker in Gujarat cut costs by switching to recycled feedstock using AI-driven material sorting. These aren’t future dreams. They’re today’s wins. And they’re all powered by the same thing: smart use of new technology.