Production Processes in Manufacturing: How Things Are Actually Made in India

When you hear production processes, the series of steps used to turn raw materials into finished goods. Also known as manufacturing process, it is the backbone of every factory, big or small, across India. It’s not just about machines humming on a line. It’s about people, timing, materials, and decisions made every minute to keep costs low and quality high. Whether it’s a smartphone assembled in Tamil Nadu or a plastic container molded in Gujarat, every product follows a path—some simple, some complex—that turns idea into item.

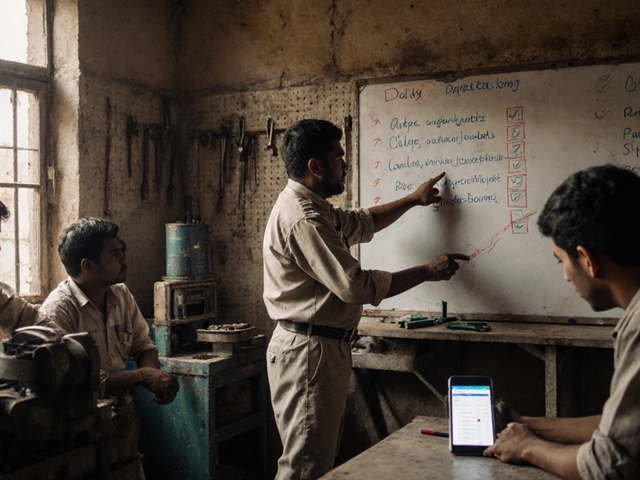

Good production processes, the organized methods used to create goods efficiently and consistently. Also known as manufacturing workflow, it is the structured sequence of operations that turn inputs into outputs. don’t happen by accident. They’re built using tools like the 5 M's of manufacturing, Manpower, Machines, Materials, Methods, and Measurement—the core pillars every small factory relies on. Also known as manufacturing principles, these are the fundamentals that separate shops that survive from those that don’t. You can’t skip Measurement if you want to qualify for government subsidies. You can’t ignore Methods if you’re trying to cut waste. And you can’t ignore Manpower—because even the most automated line still needs someone to load, check, and fix it.

These processes vary wildly depending on what’s being made. A food processing unit might use batch processing, making products in fixed quantities at set intervals, ideal for small-scale or custom runs. Also known as discrete production, it’s common in Indian spice and snack factories. A textile mill might run continuous processing, a non-stop flow of material through machines, perfect for high-volume output like fabric or yarn. Also known as flow production, it’s how big players like Reliance keep up with demand. And an electronics maker? They use hybrid systems—some automated assembly, some manual inspection—because you can’t robotize every tiny component yet.

What’s clear from the factories we’ve looked at is that the best production processes aren’t the flashiest. They’re the ones that adapt. They respond to material delays. They handle power cuts. They train workers to spot a bad solder joint before it becomes a recalled device. The most successful manufacturers in India don’t just follow a checklist—they tweak, test, and improve every day. That’s why Tamil Nadu leads in electronics exports, and why small makers in Uttar Pradesh are winning contracts with global brands.

Below, you’ll find real stories from Indian factories—how startups secured their first production partner, how small workshops cut costs using the 5 M’s, how food processors picked the right line for their product, and why some manufacturers still rely on hand tools instead of robots. These aren’t theory pages. These are maps. And they show exactly how things get made in India today.