Samsung India Export: How India’s Electronics Manufacturing Powers Global Supply Chains

When you think of Samsung India export, the massive flow of smartphones, TVs, and other electronics made in India and shipped worldwide. It's not just a company moving product—it's India becoming a core part of the global electronics supply chain. Samsung’s plant in Noida is the world’s largest mobile phone factory, turning out over 100 million devices a year. Almost all of them are exported—to Europe, Africa, the Middle East, and beyond. This isn’t luck. It’s the result of policy changes, local supply chains, and factories built to scale.

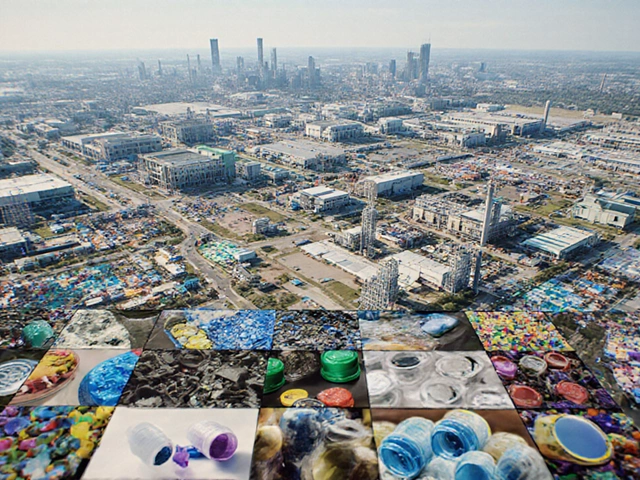

India’s electronics export growth is tied to Tamil Nadu electronics, the state that shipped over $12 billion in electronics in 2024. Places like Chennai and Sriperumbudur are packed with factories making everything from circuit boards to inverters. These aren’t just assembly lines—they’re full manufacturing hubs with local suppliers for plastics, batteries, and metal parts. The electronics manufacturing India, the full ecosystem of factories, engineers, and logistics that now produce smartphones, medical devices, and EV components locally is no longer a dream. It’s happening. And Samsung is just one player in a much bigger game.

What makes this work? It’s not just low labor costs. It’s government incentives, port access, and companies like Samsung investing in local training and component sourcing. You can’t export what you don’t make. And India is making more every year. The posts below show you how this system actually works—from the factory floor to the shipping container. You’ll see who’s winning, what’s changing, and how small manufacturers are getting pulled into this global machine.